News

How HV Interlocks Work to Ensure Safety and Prevent Disaster

High-voltage (HV) interlock is an essential safety mechanism that prevents unauthorized access to high-voltage equipment, which could lead to dangerous and potentially lethal situations. HV interlock systems are commonly used in industrial and scientific applications, such as particle accelerators, medical equipment, and high-voltage power supplies. In this article, we will discuss how HV interlock works, its different types, and its importance in ensuring safe and reliable operation.

How Does HV Interlock Work?

HV interlock works by ensuring that high-voltage equipment is only energized when certain safety conditions are met. This is achieved by using interlocking mechanisms that prevent access to the high-voltage circuitry when the equipment is in operation. The interlocking mechanism can be mechanical or electrical, depending on the type of equipment and the level of safety required.

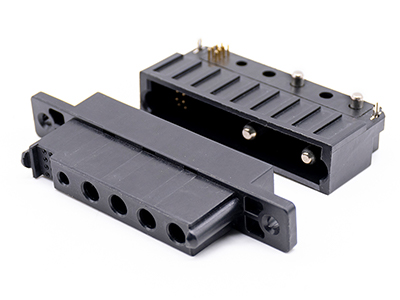

Mechanical HVIL Connector systems use physical barriers, such as doors, covers, or locks, to prevent access to high-voltage equipment. For example, in a particle accelerator, the HV interlock system may use doors that can only be opened when the accelerator is not in operation. This ensures that the high-voltage circuitry is only accessible when the equipment is safe to access.

Electrical HV interlock systems use sensors and switches to detect certain conditions, such as the presence of a person or an object in the vicinity of high-voltage equipment. When these conditions are detected, the HV interlock system sends a signal to the control system, which de-energizes the high-voltage circuitry. This prevents any potential danger to personnel or damage to the equipment.

Types of HV Interlock

There are several types of HV interlock systems, each designed to meet specific safety requirements. Some of the most common types include:

- Door Interlocks: Door interlocks use mechanical locks or sensors to prevent access to high-voltage equipment when it is in operation. These interlocks are commonly used in particle accelerators, where access to the accelerator room is restricted during operation.

- Key Interlocks: Key interlocks use a key that must be inserted into a lock to enable high-voltage equipment to be energized. This ensures that only authorized personnel have access to the equipment.

- Light Curtains: Light curtains use infrared or visible light sensors to detect the presence of an object or person in the vicinity of high-voltage equipment. If a person or object is detected, the light curtain sends a signal to the control system, which de-energizes the high-voltage circuitry.

- Pressure Mats: Pressure mats are used to detect the presence of a person or object in a specific area. When pressure is applied to the mat, it sends a signal to the control system, which de-energizes the high-voltage circuitry.

Importance of HV Interlock

The importance of HV interlock cannot be overstated. HV equipment can be lethal if not handled properly, and unauthorized access to high-voltage circuitry can result in severe injury or even death. HV interlock systems are designed to prevent such incidents by ensuring that high-voltage equipment is only energized when it is safe to do so.

In addition to safety, HV interlock systems can also improve equipment performance and reduce downtime. By preventing unauthorized access, HV interlock systems prevent accidental damage to equipment and reduce the risk of equipment failure due to tampering or mishandling.

HV Interlocks: Essential Safety Mechanisms for High-Voltage Equipment

HV interlock is an essential safety mechanism that ensures that high-voltage equipment is only energized when certain safety conditions are met. The different types of HV interlock systems are designed to meet specific safety requirements, and each has its advantages and disadvantages. The importance of HV interlock in ensuring safe and reliable operation cannot be overst Please write in English language.

To further enhance the safety of the HV system, some interlocks may also be designed to prevent unauthorized personnel from accessing the equipment. For example, an interlock system can be configured to require a special key or access code to open a cabinet door or panel that provides access to the HV components.

In addition to protecting people from potential harm, HV interlocks can also protect the equipment from damage due to improper operation or maintenance. For example, an interlock can prevent a circuit breaker from being closed while the equipment is still energized, which could cause arcing and damage to the breaker contacts. Similarly, an interlock can prevent a motor from being started while a protective cover is still in place, preventing damage to the motor or the cover.

Overall, HV interlocks play a crucial role in ensuring the safe and reliable operation of high-voltage equipment. By preventing unsafe or improper actions and providing feedback to the operator, interlocks can help reduce the risk of accidents and equipment damage. As technology continues to advance, it is likely that new and improved interlock systems will be developed to meet the evolving needs of the industry.