News

The Ultimate Guide to Forklift Battery Connectors

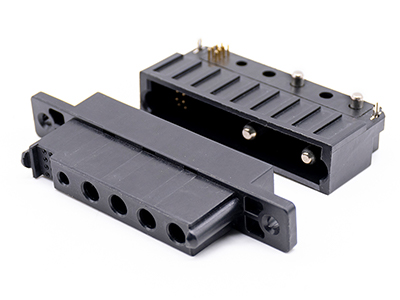

Forklift battery connectors play an essential role in the efficient and safe operation of electric forklifts. These connectors are responsible for transmitting electric power from the battery to the forklift’s motor and other electrical components. This article will explore the importance of forklift battery connectors, their types, how to maintain them, and tips for choosing the right one for your needs.

The Importance of Forklift Battery Connectors

Forklift battery connectors are crucial for several reasons:

- 1. Power Transfer: They enable the smooth transfer of electrical power from the battery to the forklift’s motor, ensuring optimal performance and preventing power loss.

- 2. Safety: High-quality connectors minimize the risk of electrical shorts, sparks, and other hazards that could lead to accidents or damage to the forklift.

- 3. Longevity: Durable and well-maintained connectors help prolong the life of your forklift’s battery, reducing the need for frequent replacements and saving you money in the long run.

Maintaining Forklift Battery Connectors

Proper maintenance of forklift battery connectors is essential to ensure their longevity and optimal performance. Here are some tips for maintaining your connectors:

- 1. Inspect Regularly: Regularly inspect your connectors for signs of wear and tear, such as cracks, corrosion, and discoloration. Replace any damaged connectors promptly to avoid further complications.

- 2. Clean Contacts: Keep the contacts on your connectors clean and free of debris. Use a clean cloth or brush to remove dirt and grime, and apply a contact cleaner if necessary.

- 3. Tighten Connections: Ensure that all connections are tight and secure. Loose connections can cause power loss and increase the risk of electrical hazards.

- 4. Use Dielectric Grease: Apply a thin layer of dielectric grease to the contacts to prevent corrosion and improve conductivity.

- 5. Store Properly: When not in use, store your connectors in a clean, dry, and well-ventilated area to prevent damage from moisture and other environmental factors.

Choosing the Right Forklift Battery Connector

When selecting a forklift battery connector, consider the following factors:

-

- 1. Compatibility: Ensure that the connector you choose is compatible with your forklift’s battery and electrical system. Consult your forklift’s manual or consult with the manufacturer for guidance.

- 2. Amperage Rating: Choose a connector with an appropriate amperage rating for your application. Overloading a connector can result in damage to the connector or the forklift’s electrical system.

- 3. Durability: Opt for high-quality, durable connectors made from robust materials such as copper, brass, or silver-plated copper. These materials offer excellent conductivity and resistance to corrosion.

- 4. Ease of Installation: Look for connectors that are easy to install and remove, such as those with a genderless design or quick-release features.

- 5. Safety Features: Select connectors with safety features such as shrouded contacts and touch-safe housings to minimize the risk of electrical hazards.

Forklift Battery Connectors are an essential component of electric forklifts, playing a crucial role in power transfer, safety, and overall performance. Understanding the different types of connectors, maintaining them properly, and choosing the right connector for your needs can ensure your electric forklift’s efficient and safe operation.