Battery Storage

Forklift Battery Connector: Understanding Its Importance and Maintenance

Forklifts are essential equipment in many industries, from manufacturing and warehousing to construction and logistics. These machines rely on batteries to operate, and the forklift battery connector plays a crucial role in ensuring the safe and efficient transfer of power from the battery to the forklift. In this article, we will explore the importance of forklift battery connectors, their maintenance, and the consequences of neglecting them.

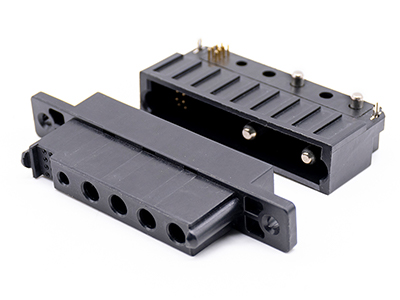

What Is a Forklift Battery Connector?

A forklift battery connector, also known as a battery plug or battery connector, is a component that connects the forklift battery to the forklift itself. It consists of two parts: a male plug and a female socket. The male plug is attached to the battery, while the female socket is attached to the forklift. When the two parts are connected, they complete an electrical circuit, allowing the battery to power the forklift.

Why Is a Forklift Battery Connector Important?

The forklift battery connector is a critical component of the forklift’s electrical system. Without a properly functioning connector, the forklift cannot receive power from the battery, rendering it useless. Moreover, a faulty connector can cause arcing, which is the discharge of electricity through the air. Arcing can lead to overheating, fires, and explosions, putting the operator and other personnel at risk.

Maintaining Forklift Battery Connectors

Forklift battery connectors require regular maintenance to ensure their proper functioning and prevent safety issues. Here are some tips for maintaining forklift battery connectors:

- Inspect the connectors regularly: Check the connectors for signs of wear and tear, corrosion, or damage. Look for cracks, breaks, or missing parts. If you notice any issues, replace the connector immediately.

- Keep the connectors clean: Dirt, dust, and debris can build up on the connectors, leading to poor conductivity and arcing. Clean the connectors regularly with a soft-bristled brush or compressed air.

- Tighten the connectors: Loose connectors can cause arcing and overheating. Make sure the connectors are tight and secure, but do not over-tighten them, as this can damage the connectors.

- Use dielectric grease: Applying dielectric grease to the connectors can prevent corrosion and improve conductivity. However, do not apply too much grease, as this can attract dirt and debris.

- Follow manufacturer’s recommendations: Consult the forklift and battery manufacturer’s recommendations for maintenance and inspection intervals.

Consequences of Neglecting Forklift Battery Connectors

Neglecting forklift battery connectors can have serious consequences, both in terms of safety and productivity. Here are some examples:

- Safety hazards: A faulty connector can cause arcing, which can lead to fires, explosions, and electrocution. These safety hazards can cause injuries or fatalities to the operator and other personnel.

- Downtime: A forklift with a faulty connector cannot operate, causing downtime and lost productivity. This can impact the bottom line of the business.

- Costly repairs: Neglecting forklift battery connectors can lead to more significant issues, such as battery damage or motor failure. These repairs can be costly and time-consuming, causing further downtime and lost productivity.

Conclusion

Forklift battery connectors are critical components of the forklift’s electrical system. They require regular maintenance to ensure their proper functioning and prevent safety hazards. Neglecting forklift battery connectors can lead to downtime, lost productivity, and costly repairs. By following the maintenance tips outlined in this article, businesses can ensure the safe and efficient operation of their forklifts and protect their personnel from harm.