News

HV Connector: The Key to High-Voltage Power Transmission

Introduction

In the realm of high-voltage power transmission, a crucial component plays a vital role in ensuring efficient and reliable electricity transfer: the HV Connector. This innovative device acts as a bridge between high-voltage equipment, facilitating the seamless flow of electricity across power grids. In this article, we will delve into the intricacies of HV Connectors, exploring their design, functionality, applications, and the significance they hold in the field of electrical engineering.

Table of Contents

- 1 What is an HV Connector?

- 2 How Do HV Connectors Work?

- 3 Types of HV Connectors

- 4 Factors Influencing HV Connector Performance

- 5 HV Connector Design Considerations

- 6 Applications of HV Connectors

- 7 Benefits of HV Connectors

- 8 Frequently Asked Questions (FAQs)

- 8.1 Can HV Connectors be used in renewable energy systems?

- 8.2 Are HV Connectors suitable for outdoor installations?

- 8.3 What safety measures should be taken when working with HV Connectors?

- 8.4 Can HV Connectors handle high temperatures?

- 8.5 How do HV Connectors contribute to power grid stability?

- 8.6 Are HV Connectors standardized globally?

- 9 Conclusion

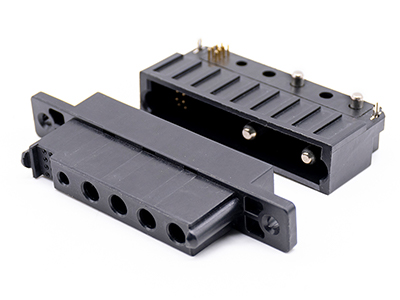

1. What is an High-Voltage Connector(HV Connector)?

At its core, an High-Voltage Connector(HV Connector) is a specialized electrical device designed to establish a secure and reliable connection between high-voltage power equipment. It enables the transfer of electricity across power grids, ensuring efficient transmission over long distances. HV Connectors are built to withstand high levels of electrical current and voltage while maintaining low resistance to minimize energy losses during transmission.

2. How Do HV Connectors Work?

HV Connectors utilize advanced engineering principles to facilitate the safe and efficient transfer of high-voltage electricity. They are engineered to provide a secure electrical connection between power equipment, such as transformers, circuit breakers, and overhead transmission lines. The connectors must effectively handle the high currents and voltages involved in high-voltage transmission, while also minimizing losses and ensuring operational reliability.

3. Types of HV Connectors

HV Connectors come in various designs and configurations, tailored to suit specific applications and voltage levels. Here are three commonly used types of HV Connectors:

3.1 Plug-and-Socket Connectors

Plug-and-socket HV Connectors, also known as bayonet connectors, offer a convenient and secure connection method. They consist of male and female components that interlock with each other to establish a reliable electrical link. This type of connector is commonly found in indoor applications, where the connectors need to be easily pluggable and removable.

3.2 Bolted Connectors

Bolted HV Connectors employ a more robust connection mechanism, utilizing bolts and nuts to firmly secure the electrical connection. This type of connector is often used in high-voltage applications that require greater mechanical strength and stability. Bolted connectors are commonly found in outdoor installations and heavy-duty industrial environments.

3.3 Clamp Connectors

Clamp HV Connectors utilize a clamping mechanism to secure the electrical connection between two conductors. They are designed to handle high-voltage applications and are particularly suitable for overhead transmission lines. Clamp connectors provide a quick and reliable method of joining conductors, enabling efficient power transfer over long distances.

4. Factors Influencing HV Connector Performance

Several factors can impact the performance and reliability of HV Connectors. Understanding these factors is essential for selecting the appropriate connector for a given application. Here are some key considerations:

- Voltage Rating: HV Connectors are rated for specific voltage levels. Choosing a connector with the correct voltage rating ensures safe and reliable operation.

- Current Capacity: HV Connectors must have adequate current-carrying capacity to handle the electrical load without overheating or excessive resistance.

- Environmental Conditions: Factors such as temperature, humidity, and exposure to corrosive substances can influence the performance and lifespan of HV Connectors. It is crucial to select connectors that can withstand the intended environmental conditions.

- Mechanical Strength: HV Connectors should possess sufficient mechanical strength to withstand mechanical stresses, vibrations, and impacts that may occur during operation or installation.

- Maintenance and Serviceability: Consideration should be given to the ease of maintenance and serviceability of HV Connectors, as periodic inspection and maintenance are essential for ensuring their long-term performance and reliability.

5. HV Connector Design Considerations

The design of HV Connectors plays a vital role in their overall performance and functionality. When designing HV Connectors, engineers must carefully consider various factors to optimize their performance. Some key design considerations include:

- Conductor Compatibility: HV Connectors should be compatible with the conductors they are intended to connect. This includes considerations for conductor size, shape, and material.

- Electrical Conductivity: Connectors must be designed to minimize resistance and ensure efficient electricity transfer. They should have low electrical resistance and high conductivity to minimize energy losses during transmission.

- Insulation and Dielectric Properties: HV Connectors require adequate insulation to prevent electrical arcing and maintain a safe operating environment. The choice of insulating materials and dielectric properties is critical in ensuring the longevity and reliability of the connector.

- Mechanical Integrity: HV Connectors should be designed to withstand mechanical stresses, vibrations, and environmental conditions. Robust mechanical construction and appropriate material selection contribute to the connector’s long-term performance and reliability.

- Safety Features: Designers must incorporate safety features into HV Connectors to protect against electrical shock, short circuits, and other potential hazards. This includes features such as insulation barriers, safety interlocks, and reliable grounding mechanisms.

6. Applications of HV Connectors

HV Connectors find widespread use in various industries and applications where high-voltage electricity transmission is required. Some common applications include:

- Power Generation and Distribution: HV Connectors play a crucial role in power generation plants, enabling the transmission of electricity from generators to transformers and distribution networks.

- Renewable Energy Systems: HV Connectors are essential in renewable energy systems, such as solar and wind farms, where large amounts of electricity need to be transmitted efficiently across long distances.

- Industrial Applications: HV Connectors are employed in various industrial applications, including manufacturing plants, refineries, and mining operations, where high-voltage equipment and machinery are used.

- Transportation and Infrastructure: HV Connectors are used in transportation systems, such as railways and electric vehicles, to facilitate the efficient transfer of electrical power. They are also vital in infrastructure projects, such as subways and high-speed railways.

7. Benefits of HV Connectors

HV Connectors offer several significant benefits in high-voltage power transmission:

- Efficient Power Transfer: HV Connectors minimize energy losses during transmission, ensuring that a large proportion of generated power reaches its destination.

- Reliable Electrical Connection: HV Connectors provide a secure and reliable electrical connection, maintaining operational integrity and minimizing the risk of failures and interruptions.

- Flexibility and Adaptability: HV Connectors come in various designs and configurations, allowing for flexibility and adaptability to different applications and voltage levels.

- Safety and Protection: HV Connectors incorporate safety features to protect against electrical hazards, ensuring the safety of personnel and equipment.

- Longevity and Durability: HV Connectors are built to withstand harsh environmental conditions, mechanical stresses, and high electrical currents, providing long-term reliability and durability.

8. Frequently Asked Questions (FAQs)

8.1 Can HV Connectors be used in renewable energy systems?

Absolutely! HV Connectors are extensively used in renewable energy systems, including solar and wind farms. They enable the efficient transfer of electricity generated by renewable sources across long distances, contributing to the integration of clean energy into the power grid.

8.2 Are HV Connectors suitable for outdoor installations?

Yes, HV Connectors are designed to withstand outdoor conditions. Bolted connectors and clamp connectors, in particular, are commonly used in outdoor installations, thanks to their robust construction and ability to withstand environmental elements.

8.3 What safety measures should be taken when working with HV Connectors?

When working with HV Connectors, it is crucial to follow appropriate safety protocols. This includes wearing personal protective equipment, ensuring proper grounding, and working with the necessary insulation and barriers to prevent electrical shocks or short circuits. It is recommended to receive proper training and certification before handling HV Connectors.

8.4 Can HV Connectors handle high temperatures?

HV Connectors are engineered to withstand a wide range of temperatures, including high temperatures. However, it is essential to consider the specific temperature ratings and operating conditions specified by the manufacturer to ensure optimal performance and longevity.

8.5 How do HV Connectors contribute to power grid stability?

HV Connectors play a vital role in maintaining power grid stability. They facilitate efficient power transfer, ensuring that electricity generated at power plants reaches consumers without interruptions. Reliable HV Connectors help prevent power outages, voltage drops, and other disturbances that can destabilize the grid.

8.6 Are HV Connectors standardized globally?

While there are international standards for HV Connectors, specific standards and regulations may vary between countries and regions. It is important to adhere to the applicable standards and regulations in the specific jurisdiction where the connectors will be used.

9. Conclusion

HV Connectors serve as the backbone of high-voltage power transmission, providing secure and efficient electrical connections across power grids. Their robust design, reliable performance, and versatility make them indispensable in various industries and applications. As technology advances and power demands continue to grow, HV Connectors will play an increasingly critical role in ensuring reliable and sustainable electricity transmission. By understanding the intricacies of HV Connectors, we can better appreciate their significance in the world of electrical engineering and power distribution. So, the next time you flick a light switch, remember the invisible hero—the HV Connector—working tirelessly behind the scenes to keep the power flowing smoothly.