News

Automotive Wiring Harness: Streamlining Electrical Connections in Vehicles

Introduction

In the world of automobiles, efficient electrical systems are crucial for ensuring optimal performance, safety, and functionality. One key component that enables seamless connectivity within vehicles is the Automotive Wiring Harness. Serving as a vital network of electrical wires, connectors, and terminals, the wiring harness plays a significant role in transmitting electrical power and signals to various components of a vehicle. In this article, we will delve into the intricacies of automotive wiring harnesses, exploring their composition, functions, and importance in modern vehicles. You can also check out “The 10 Best Automotive Wiring Harness Manufacturers In 2023”

Table of Contents

- 1 What is an Automotive Wiring Harness?

- 2 The Components of an Automotive Wiring Harness

- 3 How Does an Automotive Wiring Harness Work

- 4 The Significance of Automotive Wiring Harnesses

- 5 Types of Automotive Wiring Harnesses

- 6 Key Features to Consider in Automotive Wiring Harnesses

- 7 Installation and Maintenance of Automotive Wiring Harnesses

- 8 Common Challenges and Troubleshooting

- 9 Advancements in Automotive Wiring Harness Technology

- 10 Frequently Asked Questions (FAQs)

- 10.1 What is the purpose of an automotive wiring harness?

- 10.2 Are automotive wiring harnesses standardized across different vehicle models?

- 10.3 Can a faulty wiring harness affect vehicle performance?

- 10.4 How long do automotive wiring harnesses typically last?

- 10.5 Can an automotive wiring harness be repaired or replaced?

- 10.6 Are there any safety considerations when working with automotive wiring harnesses?

- 11 Conclusion

1. What is an Automotive Wiring Harness?

An automotive wiring harness can be likened to the circulatory system of a vehicle, as it facilitates the flow of electricity to power various electrical components and systems. It is essentially a bundled assembly of electrical wires, cables, connectors, and terminals designed to efficiently transmit electrical signals and power throughout a vehicle. These harnesses are meticulously engineered to organize and protect the multitude of wires required for the intricate electrical systems in modern automobiles.

2. The Components of an Automotive Wiring Harness

An automotive wiring harness is composed of several essential components, each serving a specific purpose in ensuring the smooth operation of a vehicle’s electrical system. Let’s take a closer look at these components:

- Wires: The backbone of any wiring harness, electrical wires act as the conduits for transmitting power and signals. They are typically made of copper or aluminum for optimal conductivity.

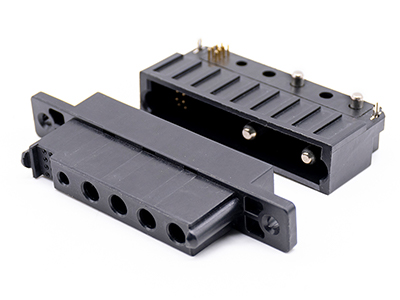

- Connectors: Connectors are used to join different wires and provide a secure and reliable electrical connection. They come in various types, such as blade connectors, pin connectors, and plug connectors.

- Terminals: Terminals are the interface between the wiring harness and the electrical components they connect to. They ensure a secure connection and often feature insulation to prevent short circuits.

- Tapes and Sleeves: Tapes and sleeves provide protection and insulation to the wires within the harness. They help prevent abrasion, moisture ingress, and potential short circuits caused by wire-to-wire or wire-to-body contact.

- Clips and Fasteners: Clips and fasteners are used to secure the wiring harness in place, preventing it from rubbing against other components or becoming entangled.

- Protective Coverings: Protective coverings, such as conduit tubes or loom, shield the wiring harness from external elements like heat, dust, and vibrations, thereby ensuring longevity and reliability.

3. How Does an Automotive Wiring Harness Work?

An automotive wiring harness acts as a central nervous system, interconnecting various electrical components within a vehicle. It works by channeling electrical power from the battery to different systems, such as the engine, lighting, audio, and sensors, ensuring proper functionality. The harness also enables communication between different vehicle control units and modules, facilitating the exchange of vital information.

To illustrate its functioning, let’s consider an example: the headlights of a car. The wiring harness delivers power from the battery to the headlight bulbs through a series of wires, connectors, and terminals. By providing a well-organized and efficient electrical pathway, the harness ensures that the headlights receive the necessary power to illuminate.

4. The Significance of Automotive Wiring Harnesses

The automotive wiring harness plays a critical role in modern vehicles, providing numerous benefits and contributing to overall performance and safety. Here are some key reasons why wiring harnesses are of utmost importance:

- Enhanced Reliability: By organizing and protecting the electrical wiring, harnesses minimize the risk of wire damage, short circuits, and electrical malfunctions. This improves the overall reliability and longevity of the vehicle’s electrical system.

- Streamlined Manufacturing Process: Wiring harnesses enable efficient assembly line production in the automotive industry. With pre-arranged wiring configurations, manufacturers can easily integrate complex electrical systems into vehicles, reducing assembly time and costs.

- Reduced Electrical Interference: The use of wiring harnesses with properly shielded wires and connectors helps minimize electrical interference, ensuring optimal performance of various electrical components. This is particularly crucial for sensitive systems like audio and communication modules.

- Simplified Troubleshooting and Repairs: In the event of electrical faults, having a structured wiring harness simplifies troubleshooting and repairs. By following the wiring diagram provided by the harness, mechanics can quickly identify the source of the problem and rectify it.

- Improved Safety: Automotive wiring harnesses are designed with safety in mind. They incorporate features such as fuse boxes and relays, which protect against electrical overload and prevent potential hazards, such as fires or damage to sensitive electronic components.

The significance of automotive wiring harnesses cannot be overstated, as they form the backbone of a vehicle’s electrical infrastructure, ensuring reliable power distribution and system functionality.

5. Types of Automotive Wiring Harnesses

Automotive wiring harnesses come in various types, tailored to meet the specific requirements of different vehicle models and systems. Let’s explore a few common types of harnesses:

- Engine Wiring Harness: As the name suggests, the engine wiring harness connects various electrical components related to the engine, such as the fuel injectors, ignition system, and sensors. It plays a vital role in ensuring the smooth operation of the engine.

- Body Wiring Harness: The body wiring harness connects electrical components within the vehicle’s body, such as the lighting system, power windows, central locking, and HVAC (heating, ventilation, and air conditioning) system.

- Chassis Wiring Harness: The chassis wiring harness integrates electrical components related to the vehicle’s chassis and frame, including the ABS (anti-lock braking system), traction control, and suspension systems.

- HVAC Wiring Harness: This harness focuses specifically on the heating, ventilation, and air conditioning systems of the vehicle, ensuring proper operation and control of these comfort features.

These are just a few examples of the diverse range of wiring harnesses used in vehicles. Each type is carefully designed and manufactured to suit the specific electrical requirements of its intended system.

6. Key Features to Consider in Automotive Wiring Harnesses

When selecting an automotive wiring harness, it is essential to consider certain key features to ensure compatibility, reliability, and optimal performance. Here are some important factors to keep in mind:

- Wire Gauge: The wire gauge determines the capacity of the wire to carry current. It is crucial to choose a harness with the appropriate wire gauge for the intended electrical load, preventing overheating and electrical failures.

- Connectivity and Compatibility: Ensure that the wiring harness is compatible with the electrical components and systems of the vehicle. This includes matching connector types, pin configurations, and communication protocols.

- Quality and Durability: Opt for harnesses made from high-quality materials that offer resistance to heat, abrasion, and chemicals. This ensures durability and longevity, even under challenging operating conditions.

- Water and Moisture Resistance: Consider harnesses with water and moisture resistance features, especially for components exposed to the elements or located in areas prone to water ingress.

- Ease of Installation: Look for wiring harnesses that come with clear instructions and are designed for easy installation. This helps save time and ensures proper integration into the vehicle’s electrical system.

By considering these features, you can select an automotive wiring harness that meets your specific needs and ensures reliable electrical connections in your vehicle.

7. Installation and Maintenance of Automotive Wiring Harnesses

Proper installation and regular maintenance of automotive wiring harnesses are crucial for optimal performance and longevity. Here are some essential tips to keep in mind:

- Follow Wiring Diagrams: Before installing a wiring harness, refer to the vehicle’s wiring diagrams and documentation to understand the correct connections and routing. This ensures accurate installation and prevents wiring errors.

- Secure Mounting: Properly secure the wiring harness using clips, fasteners, and brackets to prevent it from rubbing against other components, moving parts, or sharp edges. This protects the harness from damage and potential electrical faults.

- Avoid Excessive Heat: Ensure that the wiring harness is routed away from high-temperature areas, such as the exhaust manifold, turbochargers, or other heat sources. Excessive heat can degrade the insulation and affect the performance of the wires.

- Regular Inspection: Periodically inspect the wiring harness for signs of wear, damage, or loose connections. Look for frayed wires, cracked insulation, or corroded connectors. Promptly address any issues to prevent further damage or electrical failures.

- Protective Coverings: If the wiring harness does not already have protective coverings, consider adding additional insulation, conduit tubes, or loom to safeguard the wires from external elements and potential damage.

- Consult Professionals: For complex installations or repairs, it is advisable to seek the expertise of trained professionals who have experience working with automotive wiring harnesses. They can ensure proper installation and adherence to safety standards.

By following these guidelines, you can ensure the effective installation and maintenance of automotive wiring harnesses, promoting reliable electrical connections and minimizing the risk of electrical failures.

8. Common Challenges and Troubleshooting

While automotive wiring harnesses are designed to be robust, they can encounter certain challenges and issues over time. Let’s explore some common challenges and troubleshooting steps:

- Electrical Shorts: If an electrical short occurs in the wiring harness, it can result in malfunctioning components or blown fuses. To troubleshoot, visually inspect the harness for damaged wires or connectors. Repair or replace any faulty components.

- Intermittent Electrical Issues: Intermittent electrical problems, such as flickering lights or intermittent power loss, may be caused by loose connections within the wiring harness. Check and tighten all connectors and terminals to ensure secure connections.

- Corrosion and Oxidation: Corrosion or oxidation of connectors and terminals can disrupt electrical signals and lead to poor performance. Clean the affected connectors using a suitable electrical contact cleaner and apply dielectric grease to prevent further corrosion.

- Damaged Insulation: If the insulation on the wires within the harness becomes damaged, it can result in short circuits or electrical interference. Inspect the harness for any exposed or damaged insulation and repair or replace affected sections.

- Pinched or Chafed Wires: Pinched or chafed wires within the harness can cause electrical faults. Carefully inspect the routing of the harness, ensuring that it is free from any sharp edges or pinch points. Relocate or secure the harness to eliminate potential damage.

- Faulty Connectors: Over time, connectors may become loose or develop poor contact. Check all connectors within the harness and ensure they are properly seated and securely fastened. Replace any connectors that show signs of damage or wear.

It’s important to exercise caution when troubleshooting wiring harness issues. If you’re unsure or uncomfortable with the process, consult a professional to avoid causing further damage or compromising vehicle safety.

9. Advancements in Automotive Wiring Harness Technology

As automotive technology continues to evolve, so do the advancements in wiring harness technology. Manufacturers are constantly innovating to meet the increasing demands for higher data transmission rates, advanced electrical systems, and integration of emerging technologies. Some notable advancements include:

- High-Speed Data Transmission: With the rise of connected vehicles and advanced driver-assistance systems (ADAS), wiring harnesses are being designed to support high-speed data transmission. This enables faster and more reliable communication between vehicle control units and sensors.

- Reduced Weight and Size: Advancements in materials and manufacturing techniques have allowed for lighter and more compact wiring harness designs. This helps reduce the overall weight of vehicles, contributing to improved fuel efficiency.

- Electromagnetic Compatibility: Wiring harnesses are now being developed with enhanced electromagnetic compatibility (EMC) features. This ensures that electrical signals are not affected by electromagnetic interference, maintaining signal integrity and system performance.

- Smart Wiring Harnesses: Integration of smart technology within wiring harnesses allows for increased functionality and diagnostic capabilities. These smart harnesses can monitor electrical parameters, detect faults, and provide real-time feedback for efficient troubleshooting.

- Wireless Communication: Some manufacturers are exploring wireless communication systems as an alternative to traditional wiring harnesses. These wireless solutions eliminate the need for physical wiring, reducing complexity and enhancing flexibility in vehicle design.

These advancements in automotive wiring harness technology are driving the industry forward, enabling the development of more sophisticated and connected vehicles.

10. Frequently Asked Questions (FAQs)

10.1 What is the purpose of an automotive wiring harness?

The purpose of an automotive wiring harness is to provide a structured and organized electrical connection between various components and systems within a vehicle. It ensures the efficient transmission of electrical power and signals, enabling the proper functioning of electrical systems.

10.2 Are automotive wiring harnesses standardized across different vehicle models?

While there are certain industry standards and guidelines for automotive wiring harnesses, they are not standardized across all vehicle models. Each vehicle manufacturer may have specific requirements and designs tailored to their vehicles.

10.3 Can a faulty wiring harness affect vehicle performance?

Yes, a faulty wiring harness can significantly impact vehicle performance. It can lead to electrical malfunctions, intermittent issues, or even complete system failures. Addressing wiring harness problems promptly is crucial to ensure proper vehicle operation.

10.4 How long do automotive wiring harnesses typically last?

The lifespan of an automotive wiring harness can vary depending on several factors, including vehicle usage, environmental conditions, and maintenance. Generally, a well-maintained harness can last the lifetime of the vehicle. However, certain circumstances, such as accidents or prolonged exposure to harsh conditions, may necessitate replacement.

10.5 Can an automotive wiring harness be repaired or replaced?

In some cases, minor issues with a wiring harness, such as damaged connectors or wires, can be repaired. However, if the damage is extensive or compromises the integrity of the harness, it is often more practical to replace the entire harness.

10.6 Are there any safety considerations when working with automotive wiring harnesses?

When working with automotive wiring harnesses, it is essential to adhere to safety precautions. Disconnect the vehicle’s battery before handling the harness, use appropriate protective equipment, and avoid short circuits or electrical shocks by following proper procedures.

11. Conclusion

The automotive wiring harness is a critical component that ensures the efficient transmission of electrical power and signals within a vehicle. It plays a vital role in maintaining the reliability, performance, and safety of various electrical systems. By organizing and protecting the electrical wiring, automotive wiring harnesses enhance the overall durability and longevity of a vehicle’s electrical infrastructure.

With different types of harnesses available and advancements in technology, manufacturers are continuously improving the design and functionality of automotive wiring harnesses. Proper installation, maintenance, and troubleshooting are essential for maximizing the performance and lifespan of these harnesses.

As vehicles become more advanced and interconnected, the importance of automotive wiring harnesses will continue to grow. They are the intricate network that powers our vehicles, enabling us to enjoy the convenience, comfort, and safety features of modern automotive technology.