News

The Art of Crafting Automotive Wiring Harnesses: A Detailed Guide

If you’ve ever peeked under the hood of a car, you’ve likely seen a maze of wires skillfully bundled together. These intricate webs of cables are known as automotive wiring harnesses, and they play a vital role in ensuring the smooth functioning of modern vehicles. But have you ever wondered how these complex assemblies are made? In this article, we’ll take a deep dive into the world of automotive wiring harnesses, exploring the process from start to finish.

The Basics of Automotive Wiring Harnesses

Before we delve into the manufacturing process, let’s quickly cover the basics of automotive wiring harnesses. These harnesses are essentially a collection of wires, connectors, and terminals bundled together into a single unit. They serve as the nervous system of a vehicle, transmitting electrical signals to various components such as the engine, lights, and entertainment systems.

Design and Engineering

Creating a wiring harness begins with meticulous design and engineering. Automotive manufacturers collaborate with electrical engineers to determine the precise requirements of the harness for each vehicle model. This involves considering factors such as the number of circuits, the types of connectors needed, and the specific routing of the harness within the vehicle’s body.

Conceptualizing the Wiring Layout

During the design phase, engineers carefully plan the layout of the wiring harness. They take into account factors like the vehicle’s electrical system, the position of various components, and the necessary lengths of wires to ensure optimal functionality. Computer-aided design (CAD) software is often utilized to create detailed diagrams that act as blueprints for the production process.

Selecting Materials and Components

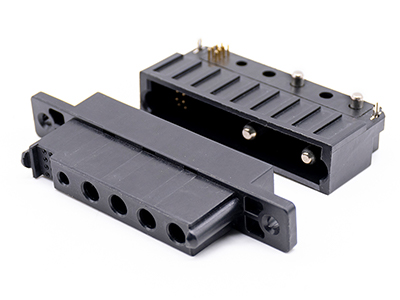

Once the design is finalized, the next step is selecting the appropriate materials and components for the wiring harness. This includes choosing the right gauge of wires, connectors, terminals, and insulating materials. Manufacturers prioritize quality and durability, opting for materials that can withstand the harsh conditions of a vehicle’s engine bay, such as high temperatures, vibrations, and exposure to fluids.

Production and Assembly

With the design and materials in place, it’s time to bring the wiring harness to life. The production and assembly process involves several intricate steps, each requiring precision and expertise.

Wire Cutting and Stripping

The first step in manufacturing a wiring harness is cutting and stripping the wires to the required lengths. This process typically involves specialized machines that accurately measure and cut the wires. Afterward, the ends of the wires are stripped of insulation to expose the conductive metal, allowing for proper connection to the connectors and terminals.

Crimping and Terminal Assembly

Once the wires are prepared, the next step is crimping and terminal assembly. This involves attaching the appropriate connectors and terminals to the stripped ends of the wires. Crimping machines are used to securely fasten the connectors, ensuring a reliable electrical connection. Skilled technicians carefully perform this task, as any faulty crimps could result in electrical failures or malfunctions.

Harness Bundling and Taping

After the individual wires have been terminated, they are meticulously bundled together into a single harness. This process involves aligning and organizing the wires according to the predetermined layout. To keep the wires neatly bundled and protected, special automotive-grade tape or plastic loom is used to wrap the harness. This provides insulation, safeguards against abrasion, and enhances the overall durability of the assembly.

Testing and Quality Control

Before the wiring harnesses are installed in vehicles, rigorous testing and quality control measures are implemented. This ensures that the harnesses meet stringent industry standards and perform flawlessly in real-world conditions. Testing may involve checks for continuity, insulation resistance, and signal integrity. Specialized equipment is used to detect any potential faults or irregularities in the harness, allowing for prompt rectification before installation.

Conclusion

Automotive wiring harnesses are a testament to the intricate craftsmanship and engineering prowess that goes into the production of modern vehicles. From the initial design phase to the final quality checks, every step in the manufacturing process is meticulously executed to create reliable and efficient harnesses. So, the next time you pop the hood of your car, take a moment to appreciate the complexity of the wiring harness that keeps it running smoothly.