Guide

A Step-by-Step Guide to Choosing M Connectors

Introduction

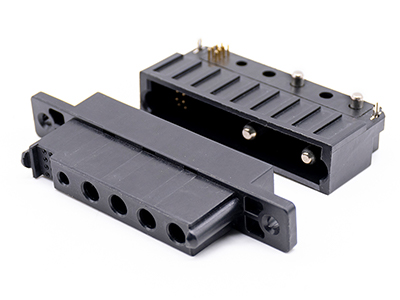

M Series connectors have become the preferred choice for engineers due to their standardized design, high reliability, and diverse model options. From the compact M5 to the high-power M16, each model has its unique advantages and application scenarios.

This article provides a comprehensive M Series connector selection guide, detailing how to choose the right connector based on electrical, mechanical, and environmental requirements, along with practical selection advice.

Overview of M Series Connectors

M Series connectors are a type of circular connector named for their metric thread (Metric Thread) locking mechanism. Common models include:

M5 Connector: Compact and small, ideal for space-constrained applications such as sensors and micro devices.

M8 Connector: Medium-sized, commonly used in industrial automation and sensor connections, suitable for moderate current and signal transmission.

M12 Connector: A “star product” in the industrial field, widely used in industrial networks, fieldbus, and power connections, with some models supporting high-frequency signal transmission.

M16 Connector: Larger in size, designed for high-current and high-voltage applications such as motor drives and power distribution.

Each model has specific electrical and mechanical properties, and selection should be based on actual requirements.

Key Factors for Selecting M Series Connectors

1. Electrical Parameters

Rated Current and Voltage: Different M Series connectors support varying current and voltage ranges. For example, M12 connectors typically support 4A-12A, while M16 connectors can handle higher currents (e.g., 16A or more).

Impedance and Signal Integrity: For high-frequency signal transmission, choose low-impedance connectors to minimize signal loss. For instance, D-coded M12 connectors are designed for Ethernet communication with excellent impedance matching.

Contact Resistance: Low contact resistance helps reduce power loss and heat generation, ensuring system stability. High-quality gold-plated contacts can significantly lower contact resistance.

2. Mechanical Parameters

Size and Mounting Style: Select the appropriate model based on device space and mounting requirements. For example, M5 is suitable for compact spaces, while M16 is ideal for high-power applications.

Mating Cycles and Durability: In industrial environments, connectors must withstand frequent mating. Choosing durable models (e.g., M12) can extend service life. Some M12 connectors offer over 500 mating cycles.

IP Rating: Choose the appropriate IP rating (e.g., IP67 or IP68) based on environmental needs to ensure reliability in damp or dusty conditions.

3. Environmental Requirements

Temperature Range: M Series connectors typically operate within a temperature range of -40°C to +85°C, with some models supporting higher temperatures. Selecting the right model for the application environment is critical.

Chemical Resistance: In environments exposed to chemicals, choose connectors made from corrosion-resistant materials (e.g., stainless steel or gold-plated contacts). For example, connectors in the food processing industry may need to withstand cleaners and disinfectants.

Vibration and Shock Resistance: In industrial settings, connectors must exhibit excellent vibration and shock resistance to ensure stable connections. For instance, automotive electronics require connectors that can endure vehicle vibrations.

Steps for Selecting M Series Connectors

Step 1: Define Application Requirements

- Determine the connector’s purpose (signal transmission, power distribution, data communication, etc.).

- Understand electrical requirements such as current, voltage, and signal type (analog, digital, high-frequency).

- Evaluate installation space, mating frequency, and environmental conditions (temperature, humidity, vibration, etc.).

Step 2: Choose the Right Model

Select the appropriate model (M5, M8, M12, or M16) based on electrical and mechanical needs.

For example:

- Small sensor connections: Choose M5 or M8.

- Industrial Ethernet communication: Choose M12.

- High-power distribution: Choose M16.

Step 3: Verify Environmental Suitability

- Check the connector’s IP rating, temperature range, and chemical resistance to ensure compatibility with the application environment.

- For example, outdoor applications require connectors with an IP67 or higher rating.

Step 4: Test and Validate

- Test the connector’s performance in real-world applications to ensure it meets electrical, mechanical, and environmental requirements.

Popular M Series Connector

Amphenol M12: Amphenol, a global leader in connector manufacturing, offers M12 connectors known for high reliability and durability, widely used in industrial automation and automotive electronics.

LEMO M Series: LEMO’s M Series connectors are renowned for their precision design and high-end performance, suitable for medical devices, test and measurement, and aerospace applications, especially in scenarios requiring high reliability and accuracy.

M12 PCB Connector: M12 PCB connectors are designed for printed circuit boards, providing compact solutions for space-constrained electronic devices such as industrial controllers and embedded systems.

M12 Connector: As the most popular model in the M Series, M12 connectors excel in industrial networks, sensor connections, and power distribution.

Frequently Asked Questions

What are the differences between M5, M8, M12, and M16 connectors?

The main differences lie in size, current-carrying capacity, and application scenarios. M5 is suitable for small devices, M12 for industrial networks, and M16 for high-power applications.

How do I choose the IP rating for M Series connectors?

Select the IP rating based on environmental needs, such as IP67 for damp environments or IP68 for underwater applications.

Can M Series connectors be used for high-frequency signal transmission?

Yes, some M Series connectors (e.g., M12) are designed for high-frequency signal transmission, but low-impedance models should be selected.

What is the mating cycle of M Series connectors?

Typically, M Series connectors offer 100-500 mating cycles, depending on the model and manufacturer.

Conclusion

M Series connectors, with their standardized design, high reliability, and wide range of applications, have become the top choice for industrial applications. By understanding electrical, mechanical, and environmental requirements and following the selection steps, you can easily choose the right M Series connector for your needs.

Whether it’s the compact flexibility of M5 or the high-power capability of M16, M Series connectors provide stable and efficient connection solutions for diverse requirements.

If you need professional connector selection support or customized solutions, Elecpeek is your ideal partner. With years of industry experience and a comprehensive product line, we offer a full range of M Series connectors, from M5 to M16, meeting the needs of industrial automation, automotive electronics, medical equipment, and more. Contact us for expert selection advice and high-quality product support!