On-board Charger

Application of On-Board Charger in Electric Forklift Trucks

The material handling industry is experiencing a significant shift towards electrification, driven by the need for sustainable, efficient, and cost-effective solutions. Among these innovations, electric forklift trucks have become increasingly popular due to their environmental benefits and operational efficiencies. A crucial component that enhances the functionality and convenience of these electric forklifts is the on-board charger (OBC). This article delves into the application of OBCs in electric forklift trucks, emphasizing their relationship, advantages, and technological advancements.

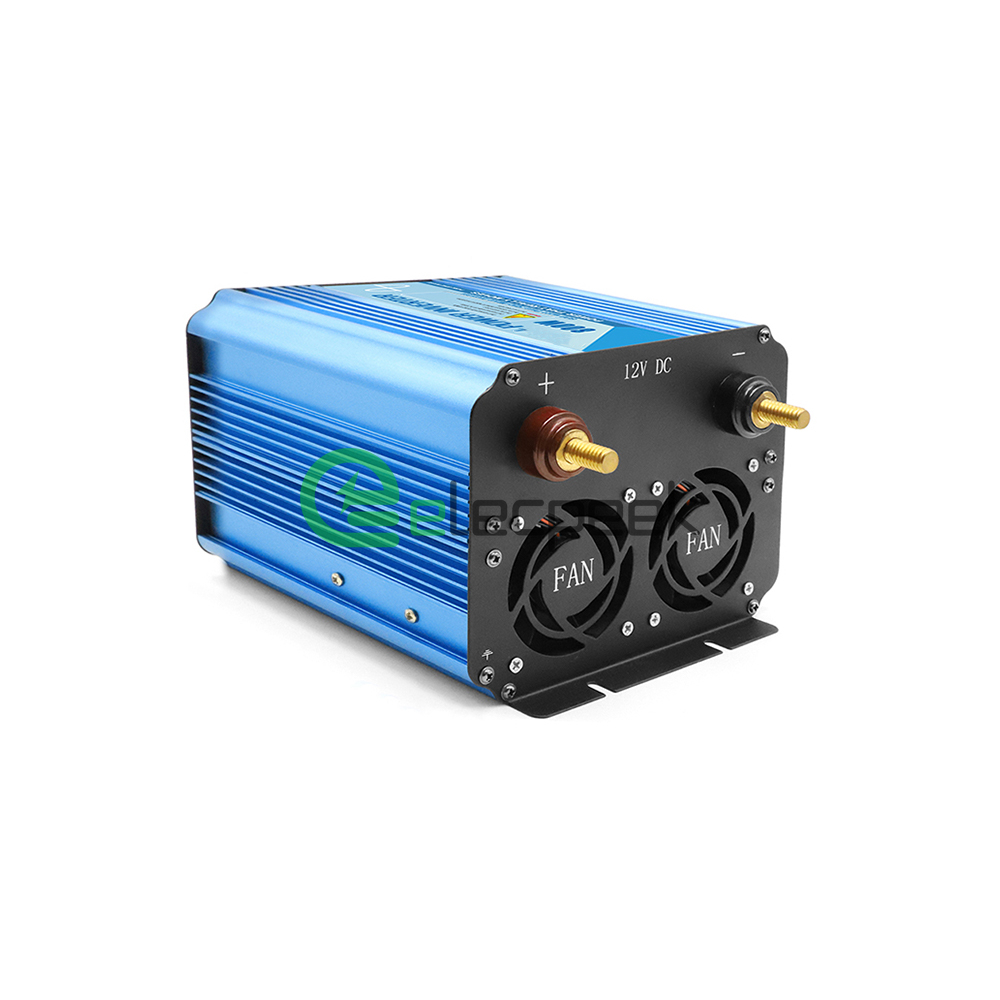

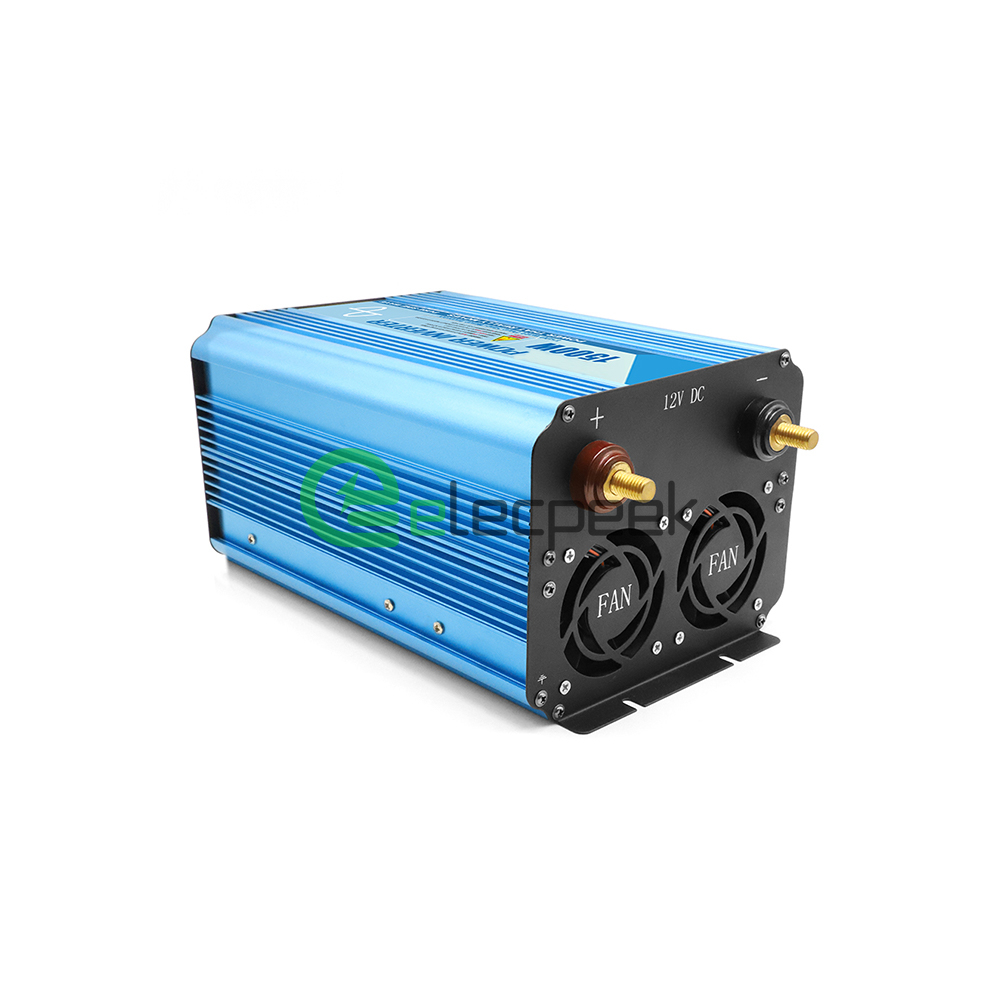

Understanding the On-Board Charger

An OBC is a device integrated into electric vehicles, including electric forklift trucks, that converts alternating current (AC) from the power grid into direct current (DC) to charge the vehicle’s battery. The integration of the charger within the vehicle itself offers significant flexibility and convenience, as it allows the forklift to be charged using standard electrical outlets without the need for specialized external charging infrastructure.

Key Components of an On-Board Charger

- Power Electronics: These components are responsible for converting AC to DC efficiently and safely.

- Control Systems: These manage the charging process, including voltage regulation, temperature control, and communication with the battery management system (BMS).

- Safety Features: These include overcurrent protection, short-circuit protection, and thermal management to ensure safe operation.

Advantages of On-Board Chargers in Electric Forklift Trucks

- Convenience and Flexibility: One of the primary advantages of OBCs is the convenience they offer. Electric forklift trucks equipped with OBCs can be charged at any location with a standard electrical outlet. This eliminates the need for dedicated charging stations, making it easier to integrate electric forklifts into existing operations without significant infrastructure changes.

- Reduced Downtime: OBCs facilitate opportunity charging, allowing electric forklift trucks to be charged during breaks or idle periods. This practice reduces downtime and increases productivity, as forklifts are less likely to be out of operation due to low battery.

- Cost Savings: By reducing the need for expensive external charging infrastructure, OBCs lower the initial investment required to transition to electric forklifts. Additionally, they allow for opportunity charging, maximizing battery life and reducing the frequency of deep discharge cycles, leading to long-term cost savings on battery replacements and maintenance.

- Enhanced Safety: OBCs are equipped with advanced safety features, including protections against overcharging, overheating, and electrical faults. These safety mechanisms ensure the longevity of the battery and safeguard the overall operation.

- Improved Battery Management: Modern OBCs are integrated with sophisticated control systems that communicate with the BMS. This integration allows for optimized charging, extending battery life and ensuring consistent performance.

Applications of On-Board Chargers in Various Industries

Electric forklift trucks equipped with OBCs are versatile and find applications across a wide range of industries. Here are some key sectors benefiting from this technology:

- Warehousing and Distribution: Electric forklifts are extensively used in warehouses and distribution centers for tasks such as loading and unloading goods, transporting materials within the facility, and stacking products on shelves. OBCs enhance their efficiency by allowing quick and convenient charging, ensuring the forklifts are always ready for use.

- Manufacturing: In manufacturing plants, electric forklifts are crucial for moving raw materials, components, and finished products. OBCs facilitate continuous operations by enabling opportunity charging during short breaks, reducing downtime, and maintaining high productivity levels.

- Retail: Large retail stores and supermarkets use electric forklifts for stocking shelves, managing inventory, and handling deliveries. The flexibility of OBCs allows these forklifts to be charged overnight or during off-peak hours, ensuring they are available for use during busy periods.

- Cold Storage: Electric forklifts are ideal for cold storage environments due to their zero-emission operation. OBCs ensure these forklifts can be charged within the facility, avoiding the need to move them to external charging stations and maintaining the integrity of the cold chain.

- Food and Beverage: In the food and beverage industry, electric forklifts are used for handling perishable goods, raw materials, and packaging. The convenience of OBCs allows these forklifts to be charged within the production area, ensuring seamless operations and maintaining product quality.

Technological Advancements in On-Board Chargers

- Fast Charging Capabilities: Recent advancements in OBC technology have focused on reducing charging times. Fast-charging OBCs can significantly reduce the time required to charge electric forklift batteries, enhancing operational efficiency.

- Smart Charging: Smart OBCs are equipped with advanced control systems that optimize the charging process based on various parameters such as battery state of charge, temperature, and usage patterns. This optimization extends battery life and improves overall performance.

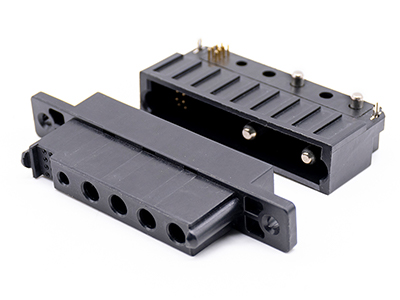

- Wireless Charging: Emerging wireless charging technologies are being integrated into OBCs, allowing for contactless charging. This innovation eliminates the need for physical connectors, reducing wear and tear and enhancing the convenience of charging electric forklifts.

- Energy Management Systems: OBCs are increasingly being integrated with energy management systems that allow for better control and monitoring of energy usage. These systems can prioritize charging during off-peak hours, reducing energy costs and minimizing the impact on the electrical grid.

The integration of OBCs with electric forklift trucks represents a significant advancement in material handling technology. By providing convenience, flexibility, and enhanced safety, OBCs play a crucial role in maximizing the efficiency and productivity of electric forklifts. As technology continues to evolve, further improvements in charging capabilities can be expected, making electric forklift trucks an even more attractive option for various industries. The relationship between OBCs and electric forklift trucks is symbiotic, driving the adoption of electric vehicles in material handling and contributing to a more sustainable and efficient future.