News

Demystifying the Automotive Wiring Harness: A Comprehensive Guide

The automotive wiring harness is a critical component in modern vehicles, responsible for transmitting electrical power and signals between different parts of the car. This essential system is often overlooked, but it plays a vital role in ensuring the smooth operation of your vehicle. In this article, we will dive deep into the world of automotive wiring harnesses, exploring their functions, components, and common issues.

Understanding the Automotive Wiring Harness

An automotive wiring harness is a network of insulated wires, connectors, and terminals that transmit power and signals throughout a vehicle. It serves as the central nervous system of the car, enabling communication between various components, such as the engine, transmission, and electronic control modules. A well-designed wiring harness ensures efficient and reliable operation, as well as simplifies the installation and maintenance of automotive electronics.

Key Functions

The primary functions of an automotive wiring harness include:

- Power Distribution: The wiring harness distributes power from the battery and alternator to various components, such as the starter, headlights, and dashboard.

- Signal Transmission: It allows electronic control modules (ECMs) to communicate with sensors, actuators, and other devices, enabling the smooth operation of systems like engine management, transmission control, and advanced driver-assistance systems (ADAS).

- Electrical Grounding: The wiring harness provides a common ground for all electrical components, ensuring proper voltage levels and preventing electrical interference.

Components of an Automotive Wiring Harness

The main components of an automotive wiring harness are:

- Wires and Cables: These are the fundamental building blocks of the wiring harness, responsible for transmitting power and signals. They come in various sizes and insulation materials, depending on the requirements of the specific application.

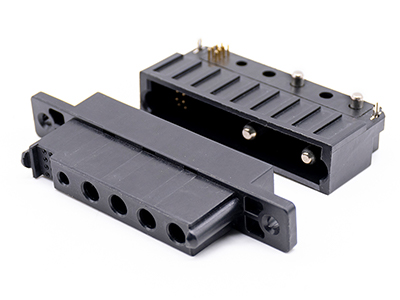

- Connectors and Terminals: Connectors and terminals are used to join wires and cables to different components. They come in various shapes and sizes, and are usually made of corrosion-resistant materials to ensure reliable connections.

- Protective Coverings: To protect the wires and cables from extreme temperatures, abrasion, and moisture, they are often wrapped in protective materials like vinyl, PVC, or braided sleeves. These coverings also help organize and route the wires, making installation and maintenance easier.

- Electrical Components: In addition to wires and connectors, an automotive wiring harness may also include electrical components such as fuses, relays, and circuit breakers. These devices provide protection and control for various electrical systems.

Common Issues with Automotive Wiring Harnesses

While modern automotive wiring harnesses are designed to be durable and long-lasting, they can still encounter various issues due to wear and tear, environmental factors, or manufacturing defects. Some common wiring harness problems include:

- Corrosion: Exposure to moisture or chemicals can cause corrosion on terminals and connectors, leading to poor electrical connections and intermittent issues.

- Physical Damage: Wires and cables can suffer from physical damage due to abrasion, impact, or excessive heat, resulting in short circuits or open circuits.

- Rodent Damage: Rodents like mice and rats are known to chew on automotive wiring, causing extensive damage and potentially dangerous electrical issues.

- Poor Connections: Loose, damaged, or improperly seated connectors can cause intermittent electrical problems or even complete system failure.

- Overheating: Insufficient cooling or excessive electrical load can cause wiring and components to overheat, leading to insulation breakdown and potential short circuits.

Proper Maintenance and Repair

To ensure the longevity and reliability of your automotive wiring harness, it’s essential to practice proper maintenance and address any issues as soon as they arise. Here are some tips for keeping your wiring harness in good condition:

- Regular Inspections: Periodically inspect the wiring harness for signs of wear, damage, or corrosion. Pay particular attention to areas exposed to heat, moisture, or abrasion.

- Protective Measures: Use appropriate protective materials to shield wires and cables from heat, moisture, and abrasion. Ensure that wires are properly routed and secured to avoid damage.

- Address Issues Promptly: If you notice any issues with your wiring harness, such as flickering lights, intermittent electrical problems, or warning lights on the dashboard, consult a professional mechanic for diagnosis and repair.

- Use Quality Components: When replacing or repairing your wiring harness, always use high-quality components from reputable manufacturers. This will ensure reliable operation and reduce the risk of future issues.

Common types of automotive wiring harnesses

Fakra Connector Cable

A Fakra connector cable is a type of coaxial cable that is commonly used for connecting automotive antennas and other RF (radio frequency) devices. The Fakra connector is a standardized connector that was developed by the German automotive industry, and it is designed to provide a reliable and secure connection for RF signals.

Fakra connectors are available in a variety of colors, which helps to ensure that the correct cable is used for each application. The color-coding also helps to prevent mismatches, which can cause signal loss and other problems.

Fakra connector cables come in different lengths and configurations, such as straight, angled, or right-angled connectors, depending on the specific application. They are also available in different impedance values, such as 50 ohm or 75 ohm, to match the impedance of the devices being connected.

HVIL Connector Cable

HVIL stands for High Voltage Interlock Loop. HVIL cable is a specialized cable used in electric and hybrid vehicles to provide a safety interlock system that ensures the electric motor and high-voltage battery are disconnected from the rest of the vehicle when the vehicle is being serviced or repaired.

The HVIL cable is typically a shielded cable with two conductors that are used to complete the interlock loop. One end of the cable is connected to the high-voltage battery, while the other end is connected to the service plug. The interlock loop must be complete for the vehicle to operate, and it is broken when the service plug is disconnected, thereby preventing any electrical shock hazards to the personnel working on the vehicle.

HVIL cables have to meet strict safety standards and are designed to withstand high voltages and currents. They are typically color-coded orange to identify them as high-voltage components and are constructed with materials that can withstand the harsh environment of automotive applications.

EV Charging Cable

An EV charging cable is a specialized cable used to connect an electric vehicle (EV) to a charging station or other power source. EV charging cables are designed to transfer electrical power from the charging station to the vehicle’s battery pack, allowing the vehicle to recharge its battery.

EV charging cables come in different lengths and configurations, depending on the specific application. They also come with different connectors, such as Type 1, Type 2, and CHAdeMO, depending on the region and the type of charging station.

In addition to the connectors, EV charging cables may also have other features, such as safety mechanisms to prevent electrical shocks and overheating, and communication protocols to allow the vehicle and the charging station to exchange information about the charging process.

When selecting an EV charging cable, it’s important to consider factors such as the power rating of the charging station, the charging speed required for the vehicle, and the length of the cable needed to reach the vehicle’s charging port.

In conclusion, the automotive wiring harness is a crucial component that ensures the efficient and reliable operation of your vehicle’s electrical systems By understanding its functions, components, and common issues, you can take the necessary steps to maintain and repair your wiring harness, while also You need to choose a quality Automotive Wiring Harness Manufacturers to keep your vehicle running smoothly and safely.