News

Future Trends of Waterproof Connectors in Consumer Electronics

I. Introduction

Waterproof connectors are electronic components specifically engineered to prevent the infiltration of moisture, humidity, and other environmental elements into the connector interior. This safeguard ensures the normal operation of electronic devices in harsh or wet conditions. These connectors create a tight protective barrier through sealing mechanisms such as rubber gaskets, O-rings, or special coatings, effectively blocking moisture entry and protecting internal electrical components from water damage. They are commonly classified according to the Ingress Protection (IP) rating, which indicates their capabilities in safeguarding against solid substances and liquids.

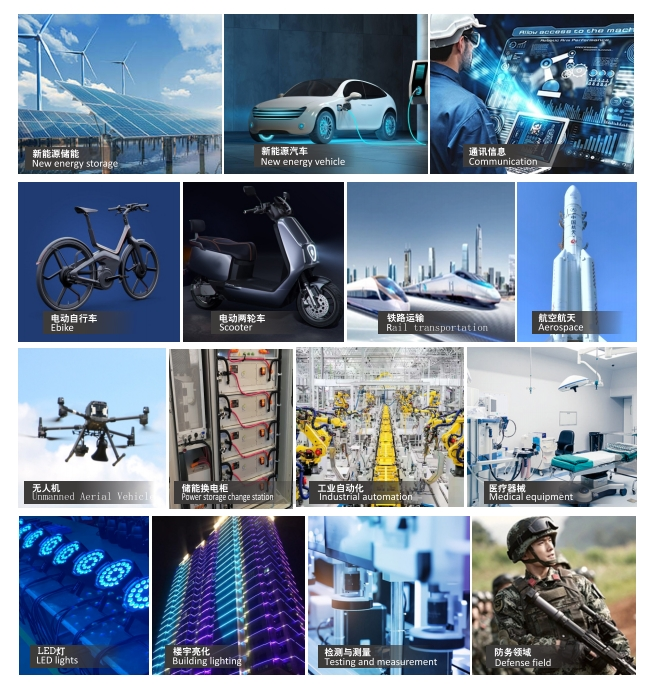

In the consumer electronics sector, waterproof connectors are widely utilized in devices exposed to outdoor environments or frequently in contact with water. With the proliferation of smart devices, wearable electronics, and portable products, waterproof connectors have become an essential part of product design.

II. Waterproof Connector Ratings

- IP68 Connectors: Compared to IP67 connectors, IP68 connectors offer enhanced waterproof performance and can endure longer underwater immersion. They are typically used in diving equipment, outdoor cameras, GPS systems, and other devices requiring long-term waterproof protection. IP68 connectors have higher requirements regarding depth and duration of immersion.

- IP67 Connectors: IP67-rated connectors can withstand immersion in water up to 1 meter deep for 30 minutes without damage. They are suitable for outdoor applications like rugged smartphones, sports watches, and portable speakers. The IP67 waterproof rating provides a relatively high level of dust and water protection, making it ideal for use in damp or rainy conditions.

- IP65 Connectors: IP65 connectors can prevent water jets from entering and are commonly used in devices that need water resistance but not full immersion, such as outdoor lighting, garden equipment, and power tools. The IP65 waterproof rating is suitable for relatively complex environments but not for long-term underwater exposure.

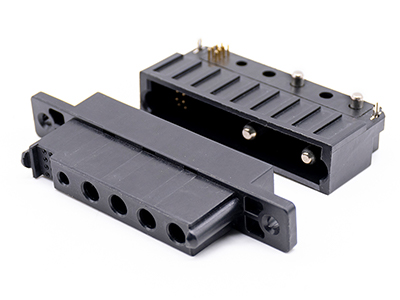

III. Types of Waterproof Connectors in Consumer Electronics

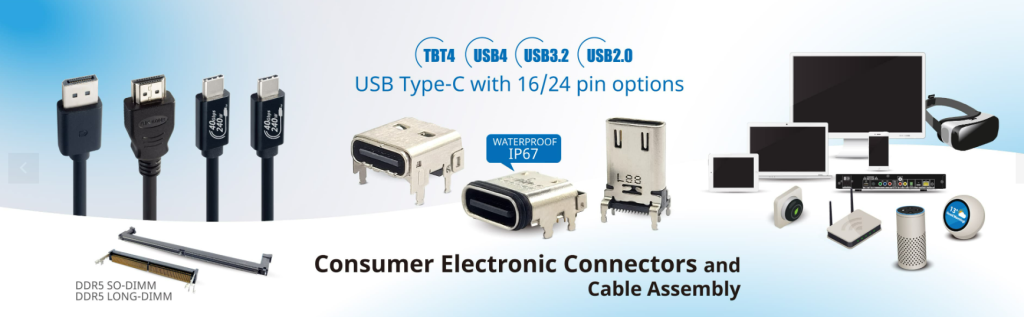

- USB Waterproof Connectors: USB-C waterproof connectors, for example, are widely used in consumer electronics like electric toothbrushes. They feature high charging speeds and broad compatibility, meeting the charging and data transmission requirements of devices in wet environments.

- HDMI Waterproof Connectors: Frequently used in outdoor display devices and underwater shooting equipment related to display applications in consumer electronics, HDMI waterproof connectors ensure the stable transmission of high-definition video signals in wet or water-rich environments.

- Aviation Plug Waterproof Connectors: High-end outdoor exploration equipment and professional waterproof cameras often employ aviation plug waterproof connectors. These connectors typically possess high strength and reliability, enabling them to adapt to harsh environments and guarantee the connection of power and signals between devices.

- RJ45 Waterproof connector: include wire mounting and panel mounting. The primary application for RJ45 waterproof connectors is in networking, communications, and industrial systems that require reliable and protected data transmission in challenging conditions.

- Circular Waterproof Connectors: Commonly found in portable consumer electronics such as waterproof speakers and flashlights, circular waterproof connectors provide reliable electrical connections with their compact structures and good waterproof capabilities.

IV. Future Development Trends of Waterproof Connectors in the Consumer Electronics Industry

A. Performance Enhancement

- Higher Waterproof and Dust–proof Ratings: As the application scenarios of consumer electronic products continue to expand, there will be a growing demand for higher waterproof and dust-proof capabilities of waterproof connectors. They need to operate stably not only in regular rain and splash conditions but also in deep diving, high water pressure environments, and extreme dust environments. The protection level will generally progress towards higher standards like IP69K.

- Excellent Electrical Performance: To meet the requirements of high-speed data transmission and high-power charging, waterproof connectors will have lower resistance, capacitance, and inductance to reduce signal attenuation and energy loss. At the same time, the anti-electromagnetic interference and electromagnetic compatibility performance will be enhanced to ensure the stability and accuracy of signal transmission in complex electromagnetic environments.

- Enhanced Mechanical Performance: High-strength and high-toughness materials will be used to improve the vibration resistance, shock resistance, and bending resistance of waterproof connectors. This ensures that the connection remains stable during the frequent use and movement of consumer electronic products, is not easily damaged, and has an extended service life.

B. Technological Innovation

- Integration and Multi–functionality: Waterproof connectors will be integrated with functions such as wireless charging, near-field communication, and sensors to form a comprehensive connection module with multiple functions. This will reduce the internal space occupation of consumer electronic products and enhance the integration and intelligence level of the products.

- High-Speed Transmission Technology: Support for high-speed data transmission standards such as 5G, 8K video, and high-speed USB4 will be provided to meet the needs of consumer electronic products for high-definition video transmission, fast download of large files, and real-time data interaction, achieving faster data transmission speeds and higher bandwidths.

- New Sealing Technology: More efficient and reliable sealing materials and structures, such as nano-sealing materials and intelligent sealants, will be developed to further improve the waterproof performance and achieve better functions such as dust prevention, moisture prevention, and oil pollution prevention, adapting to more complex environments.

- Integration of Wireless Connection Technology: With the development of wireless technology, wireless waterproof connector technology will continue to mature. Device connections will be realized through wireless communication methods such as Bluetooth and Wi-Fi, reducing the dependence on traditional wired waterproof connectors and improving the convenience and flexibility of using consumer electronic products.

C. Materials and Processes

- Application of New Materials: New materials with higher weather resistance, corrosion resistance, high temperature and low temperature resistance, such as high-performance engineering plastics, special rubbers, and new metal alloys, will be applied to improve the performance and reliability of waterproof connectors in various harsh environments.

- Nanotechnology and Micro-Electro-Mechanical Systems (MEMS) Technology: Nanotechnology will be used to treat the surface of connectors to achieve functions such as self-cleaning and super hydrophobicity, improving waterproof and anti-fouling capabilities. The MEMS process will be used to manufacture miniature waterproof connectors to achieve smaller sizes, higher precision, and better performance.

- Additive Manufacturing Technology: Through additive manufacturing technologies such as 3D printing, personalized customization and rapid manufacturing of waterproof connectors will be realized, reducing production costs, shortening the R&D and production cycle, and meeting the diverse and personalized needs of consumer electronic products.

D. Green Environmental Protection and Sustainable Development

- Use of Environmentally Friendly Materials: Comply with environmental protection regulations and use environmentally friendly materials such as lead-free, halogen-free, and recyclable materials to reduce environmental pollution and enhance the environmental friendliness of products, conforming to the global green development trend.

- Energy Conservation and Energy Efficiency Optimization: Pay attention to energy-saving design in the design and manufacturing process, reduce the energy consumption of waterproof connectors, improve energy utilization efficiency, contribute to the overall energy conservation of consumer electronic products, and promote the development of the industry in a sustainable direction.

E. Market Expansion

- Increasing Demand in Emerging Consumer Electronics Fields: In emerging consumer electronics fields such as smart homes, wearable devices, and virtual reality, the demand for waterproof connectors will continue to increase, driving further expansion of the market scale.

- International Market Opportunities: With the development of the global consumer electronics market, waterproof connector companies will have more opportunities to expand into the international market, participate in global competition, and increase market share.

V. Conclusion

Waterproof connectors are increasingly widely used in the consumer electronics industry, ranging from smartphones and wearable devices to outdoor electronic devices and medical equipment. They provide crucial protection functions for these products. With technological progress, waterproof connectors will continue to enhance their performance in the future, becoming more miniaturized and integrated, and focusing on environmental protection design. These development trends will facilitate the wider application of waterproof connectors in the consumer electronics field and meet the evolving market demands.