Guide

How to Use Waterproof Connectors Correctly?

Waterproof connectors,including waterproof electrical connectors, waterproof wire connectors, and waterproof cable connector, are essential components in many industries, especially in environments where moisture, dust, or submersion is a concern. Whether you’re working on outdoor lighting, industrial machinery, or marine equipment, knowing how to properly use waterproof connectors can save you from costly repairs and downtime. In this guide, we’ll walk you through the basic structure, step-by-step installation process, and common applications of waterproof connectors.

1. Basic Structure and How They Work

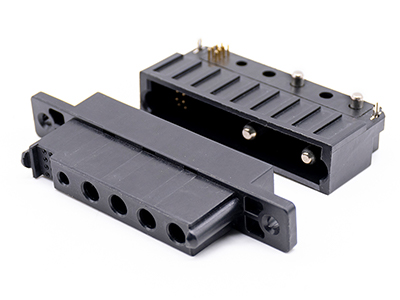

1.1 What’s Inside a Waterproof Connector?

Waterproof connectors may seem simple, but their design is quite sophisticated. Here’s what makes them tick:

- Plug and Socket: These are the parts that connect cables to devices, allowing power or signals to flow through.

- Sealing Ring (O-Ring): This small but mighty component sits at the connector’s interface, creating a tight seal to keep water and dust out.

- Shell: Made from durable materials like high-strength plastic or metal, the shell protects the internal components from damage.It’s an important safeguard for heavy duty waterproof electrical connectors used in harsh industrial environments.

- Locking Mechanism: Whether it’s threads, buckles, or clips, this feature ensures the connector stays firmly in place.In a panel mounting waterproof connector, a reliable locking mechanism is necessary to maintain a stable connection.

- Cable Clamp: This secures the cable, preventing it from being pulled out accidentally.

1.2 How Do They Keep Water Out?

The secret lies in the sealing ring. When the plug and socket are connected, the sealing ring compresses to form a watertight barrier. Most waterproof connectors come with an IP (Ingress Protection) rating, such as IP67, which means they’re dustproof and can handle temporary immersion in water.

2. Step-by-Step Guide to Installing Waterproof Connectors

Installing waterproof connectors might seem tricky at first, but once you get the hang of it, it’s straightforward. Here’s how to do it right:

2.1 Before You Start

- Check the Connector: Make sure the plug and socket match and that the cable size is compatible.

- Gather Your Tools: You’ll need wire strippers, a screwdriver, and maybe some waterproof tape.

- Clean Your Workspace: A clean area ensures no dirt or debris interferes with the seal.

2.2 Installation Steps

- Strip and Prepare the Cable:

- Use wire strippers to remove the cable’s outer sheath, exposing the wires inside.

- Trim the wires to the right length—too long, and they’ll get in the way; too short, and they might not connect properly.

- Connect the Wires:

- Follow the connector’s wiring diagram to attach the wires to the correct terminals.

- Double-check that each wire is securely fastened. A loose connection can cause problems later.

- Install the Sealing Ring:

- Place the sealing ring into its groove on the connector.

- Make sure it’s seated evenly and isn’t twisted or damaged.

- Assemble the Connector:

- Align the plug and socket, then push them together gently.

- If your connector has a locking mechanism (like threads or buckles), tighten it just enough to secure the connection. Over-tightening can damage the sealing ring.This is crucial for connectors with locking features, such as rj45 waterproof connector which are often used in network – related applications.

- Test for Waterproofing:

- Once assembled, perform a quick test by spraying water on the connector or submerging it briefly.

- Check for leaks—if you see any, disassemble the connector and inspect the sealing ring.

2.3 Pro Tips for a Perfect Installation

- Inspect the Sealing Ring: Before installation, always check the sealing ring for cracks or wear. Replace it if necessary.

- Don’t Over-Tighten: Tighten the connector just enough to secure it. Over-tightening can deform the sealing ring and compromise the seal.

- Keep It Clean: Dirt or debris can ruin the seal, so keep your workspace and tools clean.

3. Where Are Waterproof Connectors Used?

Waterproof connectors are incredibly versatile and are used in a wide range of industries. Here are some common applications and why they’re essential in these scenarios:

3.1 Outdoor Lighting

Waterproof connectors are a must-have for outdoor lighting systems like LED streetlights, garden lights, and outdoor billboards. These devices are constantly exposed to rain, snow, and UV rays, which can damage standard connectors. Waterproof connectors ensure reliable performance by creating a tight seal that keeps moisture out, even in the harshest weather conditions.

3.2 Industrial Equipment

In industrial settings, waterproof electrical connectors are used in sensors, motors, and control panels to protect against dust, vibrations, and occasional water exposure. These harsh environments can quickly degrade standard connectors, leading to equipment failure and costly downtime. Waterproof connectors provide a durable and reliable solution, ensuring uninterrupted operation.

3.3 Marine and Underwater Applications

For marine and underwater equipment like ship electronics, underwater cameras, and sonar systems, waterproof connectors are essential. Saltwater and high humidity can corrode standard connectors, but waterproof connectors are designed to resist corrosion and maintain a secure seal, even when fully submerged. This makes them ideal for demanding marine environments.

3.4 Automotive and Electric Vehicles

In the automotive industry, waterproof automotive connectors are used in car sensors, charging stations, and battery systems. Vehicles face constant challenges like vibrations, temperature changes, and exposure to water (e.g., rain or car washes). Waterproof connectors ensure stable electrical connections, preventing failures and enhancing the overall reliability of the vehicle.

3.5 Household Appliances

Waterproof connectors are also widely used in household appliances such as washing machines, water heaters, and outdoor power tools. These appliances often operate in damp or wet environments, where moisture can easily damage electrical connections. Waterproof connectors provide a safe and durable solution, ensuring the longevity and safety of everyday devices.