HVIL Connector

HVIL Connector: The Key Component in Automotive HVIL Systems

Introduction

In the world of automotive safety, High Voltage Interlock Loop (HVIL) systems play a vital role in ensuring the protection of both vehicle occupants and maintenance personnel. These systems rely on a crucial component called the HVIL connector, which forms an essential link in the HVIL circuit. This article will explore the purpose, construction, and significance of the HVIL connector in automotive applications. We will delve into its role within the HVIL system, its compatibility with HVIL cables, and its integration into the broader automotive wiring harness. So, let’s embark on this electrifying journey!

What is HVIL in Automotive?

HVIL, an acronym for High Voltage Interlock Loop, is a safety system employed in electric and hybrid vehicles to mitigate the risks associated with high-voltage components. This system ensures that high-voltage sources are isolated and de-energized before any maintenance or repair work is conducted. It comprises several components, including the HVIL connector, HVIL cable, and HVIL circuit, all working together to create a robust safety network.

HVIL Connector: The Critical Link

The HVIL connector acts as the vital link in the HVIL system, connecting the high-voltage components to the interlock circuit. It enables the transmission of control signals and interlock status information, facilitating the safe operation of the vehicle. The connector ensures a secure and reliable connection between the high-voltage system and the rest of the vehicle’s electrical infrastructure.

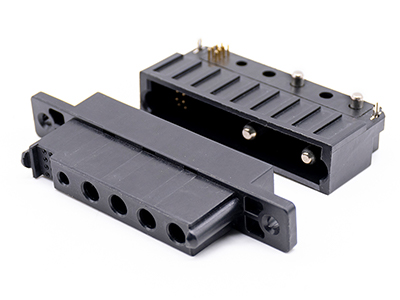

Construction and Design

HVIL connectors are engineered with meticulous attention to detail, considering the unique requirements of high-voltage applications. They feature durable materials, such as high-grade insulating polymers, to withstand the elevated electrical potentials and environmental conditions. The connectors are often designed to meet specific safety standards, ensuring proper insulation and protection against electrical shock hazards.

Compatibility with HVIL Cables

To establish a complete HVIL circuit, the HVIL connector must seamlessly integrate with HVIL cables. These cables are specifically designed to carry high-voltage signals and interlock information throughout the vehicle. The HVIL connector and cable form a secure and reliable electrical connection, allowing the interlock system to function as intended.

HVIL Connector in the Automotive Wiring Harness

In the complex network of an automotive wiring harness, the HVIL connector assumes a critical role. It serves as an interface between the HVIL circuit and the broader vehicle electrical system, allowing for seamless integration and communication. The connector is strategically positioned within the wiring harness to ensure efficient signal transmission and minimal interference.

Integration Challenges

Integrating the HVIL connector into the automotive wiring harness poses several challenges. The connector must be compatible with the existing electrical infrastructure, ensuring proper connectivity and signal integrity. Additionally, it should accommodate the unique requirements of high-voltage systems while adhering to industry-standard wiring practices.

Ensuring Safety and Reliability

The HVIL connector plays a pivotal role in maintaining the safety and reliability of the HVIL system. Its robust design and secure connection prevent inadvertent contact with high-voltage components, reducing the risk of electrical hazards. By effectively interlocking the high-voltage circuit, the connector safeguards against unintended energization and potential accidents.

FAQs (Frequently Asked Questions)

- Q: Can HVIL connectors be used in both electric and hybrid vehicles?

- A: Yes, HVIL connectors are compatible with both electric and hybrid vehicles, as they are designed to meet the unique safety requirements of high-voltage systems.

- Q: Are HVIL connectors standardized across different vehicle manufacturers?

- A: While there are certain industry standards and guidelines for HVIL connectors, specific designs and configurations may vary between vehicle manufacturers.

- Q: What safety measures are implemented in HVIL connectors to prevent electrical shocks?

- A: HVIL connectors incorporate insulating materials, shielding, and safety interlock mechanisms to minimize the risk of electrical shocks and ensure operator safety.

- Q: Can HVIL connectors withstand harsh environmental conditions?

- A: Yes, HVIL connectors are designed to withstand a wide range of environmental conditions, including temperature variations, moisture, and vibrations.

- Q: Are HVIL connectors tested for durability and reliability?

- A: Yes, HVIL connectors undergo rigorous testing to ensure their durability and reliability, including assessments for electrical performance, mechanical robustness, and environmental resistance.

- Q: Can HVIL connectors be repaired or replaced if damaged?

- A: In the event of damage to an HVIL connector, it is recommended to consult the vehicle manufacturer or a certified technician for proper repair or replacement.

Conclusion

The HVIL connector is a critical component within the HVIL system, ensuring the safe operation of electric and hybrid vehicles. Its reliable and secure connection enables the transmission of control signals and interlock information, preventing accidental energization and minimizing the risk of electrical hazards. Designed to withstand the challenges of high-voltage applications, HVIL connectors contribute to the overall safety and reliability of modern automotive systems. By understanding the significance of the HVIL connector and its integration into the automotive wiring harness, we can appreciate the sophisticated safety measures employed in electric and hybrid vehicles.