News

HVIL vs. HVPT Connector: A Comprehensive Comparison

The world of connectors can seem overwhelming, especially when it comes to HVIL Connector and HVPT Connector. Two of the most commonly used connectors in high-voltage applications are the High-Voltage Interlock Loop (HVIL) and the High-Voltage Power Terminal (HVPT). In this article, we will delve into the differences between these two connectors, exploring their functionality, applications, and key features.

Understanding High-Voltage Connectors

Before diving into the details of HVIL and HVPT connectors, it’s essential to understand the role of high-voltage connectors in general. As the name suggests, high-voltage connectors are designed to handle the increased voltage and current requirements of high-voltage systems, such as those found in electric vehicles, renewable energy, and industrial applications. These connectors typically offer features like:

- Increased insulation to prevent electrical breakdown

- Robust designs to handle high-voltage stresses

- Enhanced safety features to protect users and equipment

With this context in mind, let’s explore the unique characteristics of HVIL and HVPT connectors.

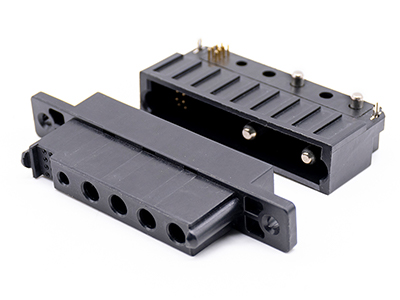

High-Voltage Interlock Loop (HVIL) Connectors: An Overview

The High-Voltage Interlock Loop (HVIL) connector is a safety-critical component commonly found in high-voltage systems. Its primary function is to ensure that the high-voltage circuit remains de-energized until the connection is fully secured. This helps safeguard both the user and the equipment from potential electrical hazards. The HVIL connector achieves this by utilizing a unique design that incorporates an interlock loop mechanism.

Key Features of HVIL Connectors

- Safety Mechanism: The interlock loop mechanism in HVIL connectors prevents accidental disconnection while the circuit is energized. If an attempt is made to disconnect the connector under load, the HVIL system will immediately de-energize the high-voltage circuit, ensuring the safety of users and equipment.

- Enhanced Insulation: HVIL connectors feature increased insulation to prevent electrical breakdown, which is essential in high-voltage environments.

- Robust Design: These connectors are designed to withstand the harsh conditions often encountered in high-voltage applications, including high temperatures, moisture, and vibration.

- Signal Transmission: In addition to providing a secure connection for high-voltage power, HVIL connectors also facilitate the transmission of low-voltage signals between connected devices.

Common Applications of HVIL Connectors

HVIL connectors are widely used in various high-voltage applications, including:

- Electric vehicles (EVs) and hybrid electric vehicles (HEVs)

- Battery management systems (BMS)

- High-voltage power distribution systems

- Renewable energy systems, such as solar power and wind turbines

High-Voltage Power Terminal (HVPT) Connectors: An Overview

High-Voltage Power Terminal (HVPT) connectors are specifically designed for high-current, high-voltage applications. These connectors provide a reliable and secure connection for power transmission in demanding environments. Unlike HVIL connectors, HVPT connectors do not incorporate an interlock loop mechanism. Instead, they focus on providing a robust and efficient connection for high-voltage power transfer.

Key Features of HVPT Connectors

- High-Current Capability: HVPT connectors are designed to handle high currents, typically ranging from a few hundred amperes to several thousand amperes, depending on the specific connector type and application.

- Increased Insulation: Like HVIL connectors, HVPT connectors feature enhanced insulation to protect against electrical breakdowns in high-voltage environments.

- Robust Design: HVPT connectors are built to endure the challenging conditions of high-voltage applications, including extreme temperatures, moisture, and vibration.

- Ease of Use: These connectors are designed for straightforward installation and disconnection, minimizing the potential for user error and ensuring reliable connections.

Common Applications of HVPT Connectors

HVPT connectors are employed in various high-voltage, high-current applications, such as:

- High-voltage power transmission and distribution

- Electric substations and switchgear

- Industrial equipment and machinery

- Renewable energy systems, including large-scale solar power and wind turbines

Comparing HVIL and HVPT Connectors: Key Differences

While both HVIL and HVPT connectors are designed for high-voltage applications, their primary differences lie in their specific functionalities and focus areas:

- Signal Transmission: high-voltage and low-voltage

HVIL connectors facilitate both high-voltage power and low-voltage signal transmission, whereas HVPT connectors are primarily focused on high-voltage power transmission. - Applications:

HVIL connectors are more commonly found in applications where user safety is a primary concern, such as electric vehicles and battery management systems. HVPT connectors, on the other hand, are more prevalent in high-current, high-voltage power transmission and distribution systems. - Mechanical Features: Interlocks vs Threads

The most obvious distinction is that HVIL connectors use interlocking features like bayonet lugs or straight plugs to lock the connector in place, while HVPT connectors utilize threaded assemblies. The interlocks in HVIL connectors provide a physical barrier that prevents separation until the load is removed. Threads alone in HVPT connectors can allow for easier disengagement but also mean the connection is more prone to loosening over time. - Electrical Features: Load Breaking vs Non-Load Breaking

HVIL connectors are designed and rated to provide load breaking, meaning they can safely interrupt electrical current when being disconnected. HVPT connectors are non-load breaking and should not be disconnected under load. Attempting to do so could result in damage, arcing, or even an explosion. - Safety Mechanism: Preventing Arc Flashes

The interlocking and load-breaking features of HVIL connectors help ensure a safe disconnect by eliminating the possibility of an arc flash. In contrast, energized disconnects of HVPT connectors could potentially lead to dangerous arc flashes due to the non-load-breaking design. For this reason, HVPT connectors should always be de-energized before disconnecting.

Choosing Between HVIL and HVPT Connectors

When deciding between HVIL or HVPT high-voltage connectors, there are a few factors to consider:

- Safety – If interlocking the connector halves for safety is important, an HVIL connector is likely needed. HVPT connectors can be more easily disconnected under load which poses safety risks.

- Current load – For high power transmission greater than 600A, an HVPT connector may be better suited as they are optimized for very high currents. HVIL connectors typically max out at 600A or below.

- Ease of use – HVPT connectors are often quicker and easier to mate and inmate since they lack the locking mechanisms of HVIL connectors. However, additional safety precautions need to be taken when connecting/disconnecting HVPT connectors live.

- Environment – Harsher industrial environments may benefit more from the robust, locked design of HVIL connectors which are less prone to vibration and shock. HVPT connectors would require more strain relief to prevent issues in high-vibration applications.

In conclusion, the choice between an HVVIL and HVPT connector depends on the specific requirements of the application, with HVIL connectors offering enhanced safety features and dual power-signal transmission, while HVPT connectors focus on robust, high-current power transmission. By understanding the differences between these two connectors, you can select the most suitable option for your high-voltage application, ensuring optimal performance and safety.