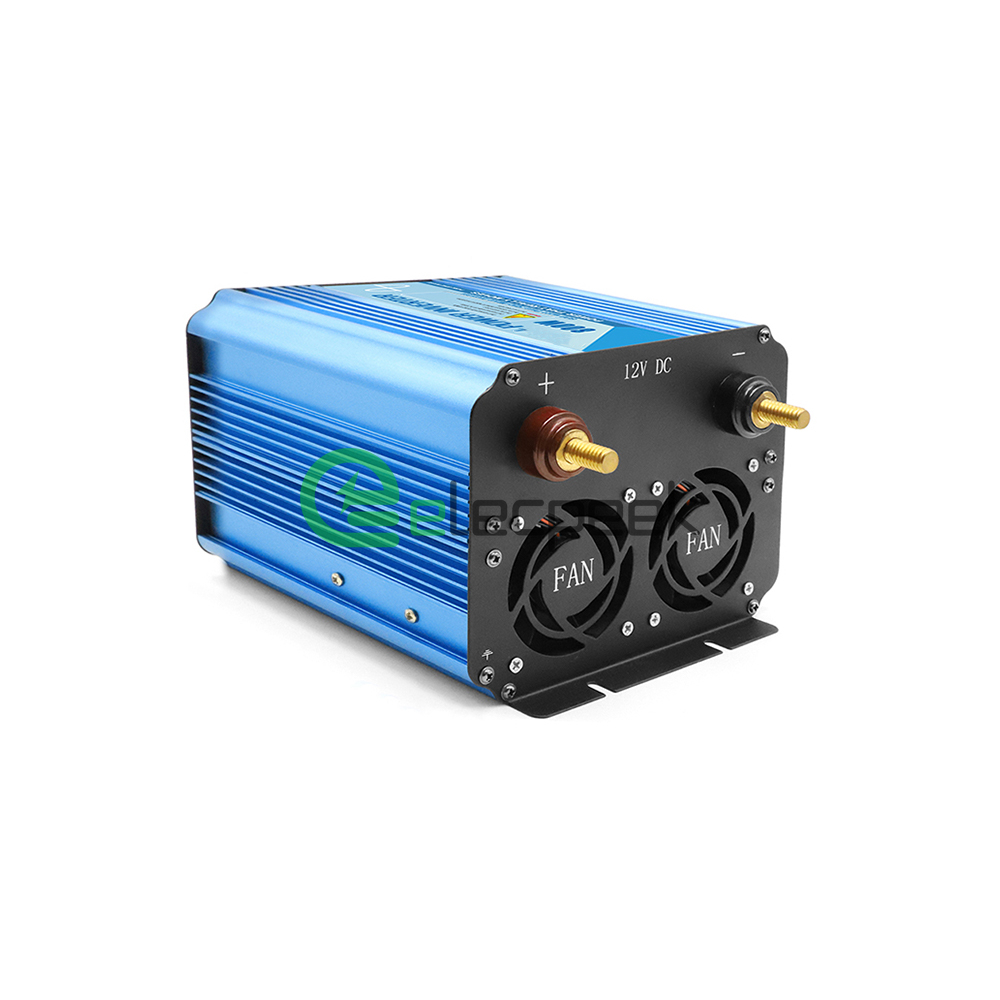

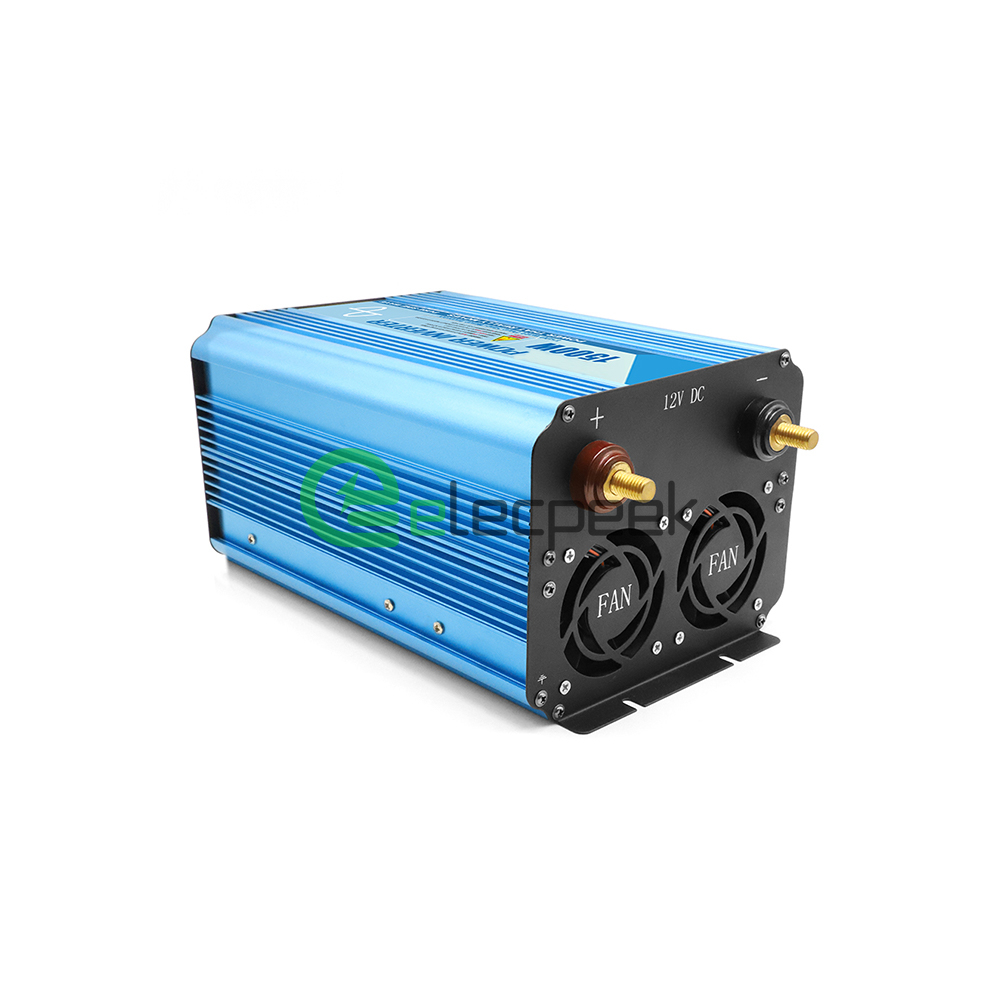

1.2KW On-board Charger

24V 48V 72V 108V 144V 360V Battery Charger for Club Car and Golf Cart Lithium Lead Acid Battery Chargers

Inquiry Form for Bulk Order?

Please fill in your details and requirements below, and our team will get in touch with you as soon as possible.

Elecpeek specializes in providing a comprehensive range of high-quality battery chargers designed specifically for Club Car and golf cart applications, compatible with both lithium-ion and lead-acid battery types. These chargers are meticulously engineered to accommodate a wide voltage spectrum, ensuring compatibility with various electric vehicle systems, including 24V, 48V, 72V, 108V, 144V, and even the more robust 360V configurations.

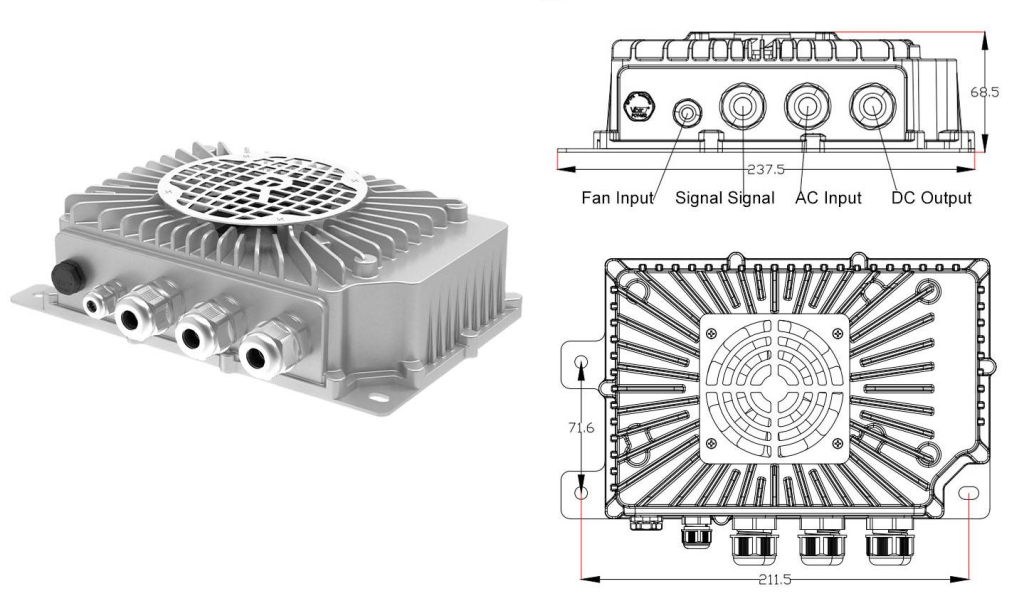

1.2KW On-board Charger Specification

1.2KW On-board Charger Series

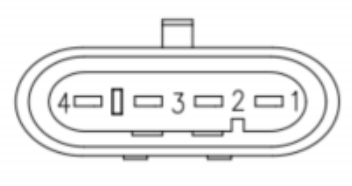

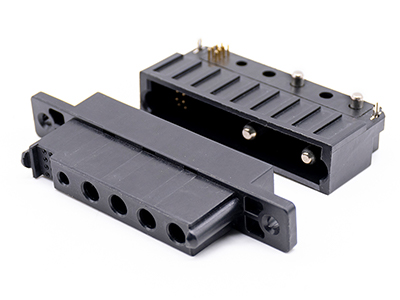

Plug and Socket Definition

Output Plug Options

Input Plug Options

Successful Projects

Project QTY: 500PCS

Item: 6.6KW On-board Charger

Location: Portland, United States

Project QTY:1200PCS

Item:20KW On-board Charger

Location:Russelsheim,Germany

Project QTY: 500PCS

Item: 6.6KW On-board Charger

Location: Portland, United States

Project QTY: 500PCS

Item: 6.6KW On-board Charger

Location: Portland, United States

Project QTY: 500PCS

Item: 6.6KW On-board Charger

Location: Portland, United States

Project QTY: 500PCS

Item: 6.6KW On-board Charger

Location: Portland, United States

Application

On-board chargers are integral components of electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs). They convert Alternating Current (AC) from the grid (or any other AC source) to Direct Current (DC) for charging the vehicle's battery. Electric boats and other marine vehicles also use on-board chargers. These chargers may need to be particularly robust to withstand the harsh marine environment.

| Weight | 6100 g | ||

|---|---|---|---|

| Input Voltage Frequency | 50Hz |

||

| Output Response Time | ≤5S |

||

| Cooling Method | Forced air cooling |

||

| Weight | 6100 g | Input Voltage Frequency | 50Hz |

| Output Response Time | ≤5S |

Cooling Method | Forced air cooling |

Electrical

| Rated Input Voltage | 220VAC |

||

|---|---|---|---|

| Input Voltage | 90~265VAC |

||

| Input Frequency Range | 45~65Hz |

||

| Starting Impulse Current | ≤10A |

||

| Input Power Factor | ≥0.99(@220Vin, Pomax) |

||

| Voltage Stabilization | ≤1% |

||

| Ripple Coefficient | ≤1% |

||

| Current Stabilization | ≤5% |

||

| Typical Efficiency | ≥93% |

||

| Humidity | 5%~95% |

||

| Ip Grade | lp67 |

||

| Communication | CAN bus control |

||

| Rated Input Voltage | 220VAC |

Input Voltage | 90~265VAC |

| Input Frequency Range | 45~65Hz |

Starting Impulse Current | ≤10A |

| Input Power Factor | ≥0.99(@220Vin, Pomax) |

Voltage Stabilization | ≤1% |

| Ripple Coefficient | ≤1% |

Current Stabilization | ≤5% |

| Typical Efficiency | ≥93% |

Humidity | 5%~95% |

| Ip Grade | lp67 |

Communication | CAN bus control |

Environmental

| Operating Temperature | -40℃~55℃ |

||

|---|---|---|---|

| Storage Temperature | -40℃~100℃ |

||

| Operating Temperature | -40℃~55℃ |

Storage Temperature | -40℃~100℃ |

| Weight | 6100 g |

|---|---|

| Dimensions | 21 × 14.2 × 7.1 cm |

| Rated Input Voltage | 220VAC |

| Input Voltage | 90~265VAC |

| Input Voltage Frequency | 50Hz |

| Input Frequency Range | 45~65Hz |

| Starting Impulse Current | ≤10A |

| Input Power Factor | ≥0.99(@220Vin, Pomax) |

| Voltage Stabilization | ≤1% |

| Ripple Coefficient | ≤1% |

| Current Stabilization | ≤5% |

| Output Response Time | ≤5S |

| Typical Efficiency | ≥93% |

| Operating Temperature | -40℃~55℃ |

| Storage Temperature | -40℃~100℃ |

| Humidity | 5%~95% |

| Ip Grade | lp67 |

| Cooling Method | Forced air cooling |

| Communication | CAN bus control |

The charging station support of OBC depends on its compatible charging interface standard, including home charging posts, public charging stations, etc.

The compatibility and standards of OBC include charging interface standards, charging rates, communication protocols, and safety standards.

The reliability and durability of OBC depend on the following factors:

- Design quality and manufacturing process

- Temperature management

- Overload protection

- Environmental adaptability

Smart features of OBC may include remote monitoring, charging appointments, charging schedule optimization, charging history, smart energy management, charging location navigation, and remote diagnostics and maintenance.

The safety of OBC is realized through measures such as overload protection, short circuit protection, temperature monitoring and strict compliance with safety standards.

Elecpeek's On-Board Charger works by converting AC power from an external source, such as a charging station or wall outlet, into DC power that can be stored in the EV battery.

The charging time for an EV using OBC depends on the battery size, charge level, and the charging speed provided by the charger. Typically, it takes between 1 to 12 hours to fully charge an EV using OBC.

Yes, a damaged or faulty OBC can result in overcharging, overcharging, or overheating the battery, which can decrease the lifespan of the battery. It is essential to ensure the proper maintenance and functioning of OBC.

OBC is used for level 1 and 2 charging and provides a lower charging speed than a DC fast charger. DC fast chargers are used for level 3 charging and can provide up to 80% charging in 30 minutes.

Yes, hybrid vehicles also use OBC to charge the battery.

Description

Description  Technical Data

Technical Data  FAQ

FAQ  Downloads

Downloads  Customization

Customization