News

The Role of HV Connectors in Energy Storage Systems

As the demand for clean energy grows, the use of energy storage systems (ESS) has become increasingly popular. These systems play a crucial role in the integration of renewable energy sources into the grid by storing excess energy and releasing it when needed. However, ESS must be equipped with high-voltage (HV) connectors that can handle the high-power output and voltage levels to ensure safe and reliable operation. In this article, we will discuss the importance of HV connectors in ESS and their key features.

HV Connector for Energy Storage Systems

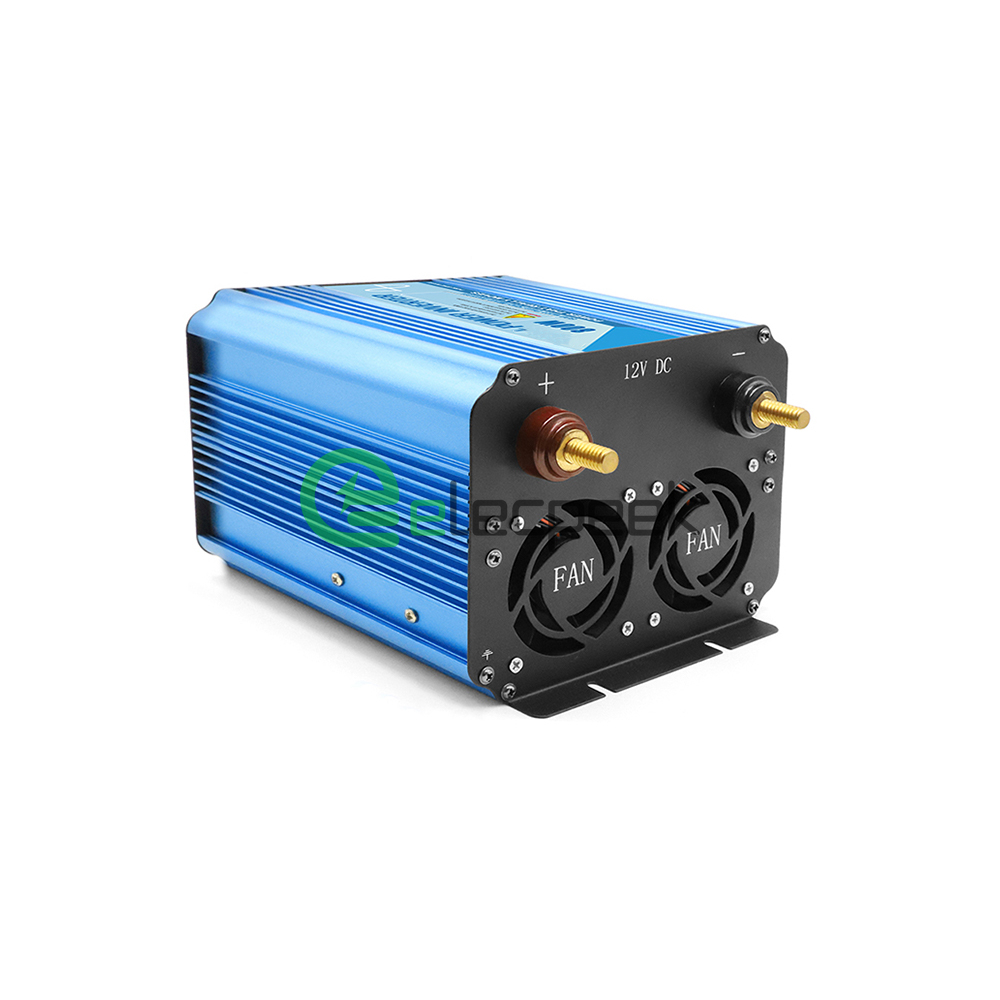

HV connectors are designed to transmit power between different parts of the ESS, such as the battery bank, inverter, and load. They are also used to connect ESS to the grid, allowing excess energy to be sold back to the utility company. HV connectors must be able to handle high voltage levels, typically between 600V to 1500V, and high current levels, which can range from several hundred to thousands of amperes.

The Importance of High-Quality HV Connectors

HV connectors are a critical component of ESS, and their failure can lead to costly downtime and safety hazards. Therefore, it is crucial to choose high-quality connectors that are designed to withstand harsh operating conditions and provide reliable and safe operation.

One of the critical features of high-quality HV connectors is their ability to handle high currents without overheating. Overheating can cause the connector to melt, leading to a catastrophic failure. High-quality connectors are typically made of materials that have low resistance, such as copper or aluminum, to minimize power loss and heat generation.

Another critical feature is the connector’s ability to withstand harsh environments, such as extreme temperatures, humidity, and vibration. ESS is often installed in remote locations, such as wind farms or solar fields, where they are exposed to harsh weather conditions. High-quality connectors are designed to withstand these conditions without degrading their performance.

Energy Storage Connector

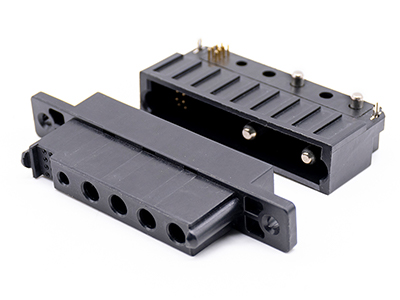

Energy storage connectors are another critical component of ESS, designed to connect the battery cells to the rest of the system. These connectors must be able to handle high voltages and currents and provide reliable and safe operation.

Energy storage connectors come in different types, including bolted and compression connectors. Bolted connectors are commonly used in low-voltage applications, while compression connectors are used in high-voltage applications. Compression connectors are designed to provide high contact pressure, ensuring a reliable and low-resistance connection.

Key Features of Energy Storage Connectors

Energy storage connectors must meet specific requirements to ensure safe and reliable operation. Some of the key features include:

- 1. High Voltage Rating: Energy storage connectors must be able to handle high voltage levels, typically between 1000V to 1500V.

- 2. High Current Rating: Energy storage connectors must be able to handle high current levels, which can range from several hundred to thousands of amperes.

- 3. Low Contact Resistance: Energy storage connectors must have low contact resistance to minimize power loss and heat generation.

- 4. Good Insulation: Energy storage connectors must have good insulation to prevent accidental electrical contact.

- 5. High Durability: Energy storage connectors must be able to withstand repeated connections and disconnections without degrading their performance.

HV connectors and energy storage connectors are critical components of ESS, ensuring safe and reliable operation. High-quality connectors that can handle high voltage and current levels and withstand harsh operating conditions are essential for the success of ESS. By choosing the right connectors for your ESS, you can ensure that it operates safely and reliably, maximizing its efficiency and lifespan.