News

Understanding MSD Connectors: Features and Applications

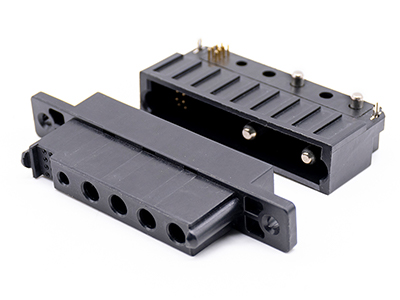

MSD connectors are specialized connectors designed for use in harsh environments where there is a risk of contamination or damage to electrical components. The connectors are particularly useful in applications where there is exposure to dust, dirt, moisture, or other contaminants that could cause electrical problems. In this article, we will explore the features of MSD connectors and their commonly used applications.

What is an MSD connector?

MSD connectors are a type of electrical connector that is designed to provide reliable connections in harsh environments. They are typically used in industrial applications where there is a risk of exposure to contaminants such as moisture, dust, dirt, and chemicals. The connectors are constructed with a sealed design that protects against these elements.

Features of MSD connectors

MSD connectors come in various sizes, shapes, and configurations to suit different applications. Some of the features that make MSD connectors suitable for harsh environments include:

- Sealed design: MSD connectors are designed with a sealing mechanism that prevents contaminants from entering the connector. The sealing mechanism may consist of gaskets, O-rings, or other types of seals.

- High-temperature resistance: MSD connectors are designed to withstand high temperatures, making them suitable for use in applications with heat exposure.

- Vibration resistance: MSD connectors are designed to withstand vibration and shock, making them ideal for use in applications where there is a risk of mechanical stress.

- Corrosion resistance: MSD connectors are typically made from materials that are resistant to corrosion, such as stainless steel or aluminum.

Applications of MSD connectors

MSD connectors are used in a wide range of applications across various industries. Some of the common applications of MSD connectors include:

- Aerospace and defense: MSD connectors are commonly used in aerospace and defense applications where there is a need for reliable and rugged connectors. They are often used in avionics, weapons systems, and communication equipment.

- Industrial automation: MSD connectors are used in industrial automation applications, such as robotics, machine control, and factory automation. They are particularly useful in applications where there is a risk of exposure to moisture, dust, or other contaminants.

- Medical equipment: MSD connectors are used in medical equipment, such as diagnostic devices, patient monitoring equipment, and surgical instruments. They are designed to withstand sterilization processes and other cleaning procedures.

- Transportation: MSD connectors are used in transportation applications, such as railways, ships, and automobiles. They are designed to withstand harsh environmental conditions like vibration, shock, and extreme temperatures.

MSD connectors are designed to provide reliable and rugged connections in harsh environments. They are constructed with a sealed design that protects against moisture, dust, dirt, and other contaminants. MSD connectors are used in a wide range of applications across various industries, including aerospace and defense, industrial automation, medical equipment, and transportation. With their high-temperature resistance, vibration resistance, corrosion resistance, and other features, MSD connectors are an ideal choice for applications where reliability and durability are essential.