On-board Charger

What Is an On board Charger?

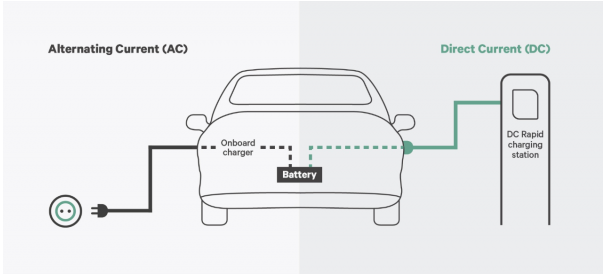

An on board charger (OBC) serves as a crucial power electronics device in electric vehicles (EVs), facilitating the conversion of AC power from external sources, such as residential outlets, into DC power for charging the vehicle’s battery pack.

The OBC engages in communication with both the vehicle controller and the charging station, determining the appropriate amount of current/power and the correct charging standard to be applied. With multiple global charging standards, such as those for Europe, North America, and China, the OBC has the capability to automatically adjust to the relevant regional standards based on data received from the EV supply equipment (EVSE) controller or vehicle controller.

In addition to its primary function, the on board charger plays a vital role in bidirectional charging modes. This means it can convert DC power from the high-voltage battery pack into AC power to support various applications, including powering AC loads (V2L), contributing to the grid (V2G), and even supplying power to other electric vehicles.

OBC Car Charger Introduction

The on board charger, situated within the vehicle, facilitates battery pack recharge through three distinct methods: Level 1, Level 2, and DC Fast Charging. Each method offers varying charging speeds and ranges.

Level 1 Charging

Utilizing a standard 120-volt household outlet, Level 1 charging can deliver up to 2.4 kW of power. This method is the slowest, requiring up to 20 hours to fully recharge a depleted battery pack.

Level 2 Charging

Level 2 charging operates with a 240-volt outlet, providing up to 19.2 kW of power. Faster than Level 1 charging, it can recharge a depleted battery pack in 4 to 8 hours, dependent on battery size and charging rate.

DC Fast Charging employs a high-voltage DC charging station, delivering up to 350 kW of power. Recognized as the fastest method, it can recharge a depleted battery pack in 30 to 60 minutes, contingent on battery size, charging rate, and the charging station’s capacity.

Working of an Onboard Charger

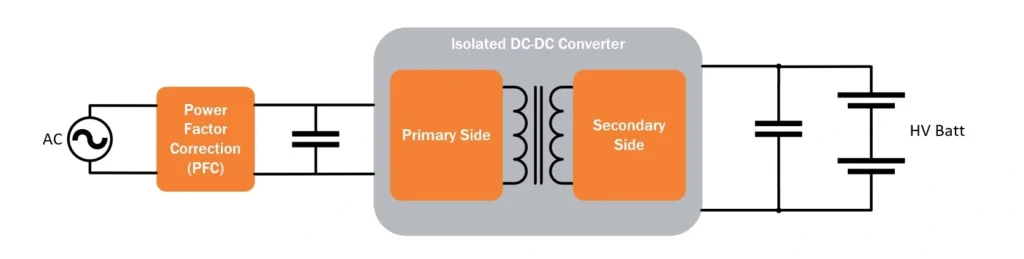

In OBCs using a rectifier, high power AC input is converted to DC power and provides Power Factor Correction. To boost the power factor to unity, a power factor correction (PFC) circuit removes harmonic distortion in the supply current and provides a current waveform that is close to a basic sine wave. This section of the charger determines whether it can use one, two, or all three alternating current phases. In addition, the DC/DC converter must isolate the power grid from the HV dc bus and the HV dc bus from the LV dc bus for safety reasons.

The second phase receives the 700V output voltage. The resultant DC signal is chopped into a square wave, that drives a transformer. This further provides the required DC voltage. An isolated CAN bus can be used to monitor and control the entire system. Digital isolators and digital isolators with integrated DC/DC power converters are used to isolate the CAN. Finally, the required voltage is supplied to the battery.

An on-board battery charger in your electric vehicle (EV) can bring forth several advantages, contributing to an enhanced driving experience. Here are some of them:

1. Convenience

With an on-board charger, you can conveniently charge your EV at home, eliminating the need to visit public charging stations. Simply plug your car into a standard outlet and let it charge overnight.

2. Flexibility

An on-board charger provides flexibility in choosing the charging method that aligns with your needs. Opt for Level 1 charging when time is abundant, or switch to Level 2 charging for quicker recharging. On a long road trip, utilize DC Fast Charging to swiftly recharge your battery and resume your journey.

3. Efficiency

A high-quality on-board charger can maximize the battery’s capacity and facilitate faster, more efficient charging. This translates to extended driving ranges and an overall improved driving experience.

4. Reliability

The onboard charger plays a critical role in the EV, and having a reliable one can prevent unexpected breakdowns and reduce maintenance costs. A dependable onboard charger ensures your EV is always ready to go when needed.

5. Safety

A top-notch onboard charger contributes to safety by safeguarding against overcharging, short-circuiting, and other electrical issues that can pose risks. This assurance allows for peace of mind during the EV charging process.

Design Considerations of OBCs

The factors that needs to be considered before designing the OBCs:

- The AC input and the required output level

- The AC input and the required output level

- The maximum power the battery pack can withstand

- Temperature cooling and space reduction

- Charging time

- Rectification of AC signal and Power Factor Correction (PFC)

- Communication between the EV and EVSE

- Safe isolation between power source and battery

The on-board chargers have many applications apart from charging the batteries of an EV. They are most commonly used in:

Hybrid electric vehicles (HEVs): Onboard chargers are used to charge the battery in hybrid electric vehicles, helping to extend the electric-only driving range of the vehicle.

Industrial equipment: Onboard chargers are used in a variety of industrial equipment, such as material handling equipment, forklifts, and aerial work platforms, to recharge the battery when the equipment is not in use.

Marine applications: Onboard chargers are used in marine applications, such as boats and yachts, to recharge the battery while the vessel is docked.

Portable power: Onboard chargers are used in portable power applications, such as portable generators, to recharge the battery when the generator is not in use.

Renewable energy systems: Onboard chargers are used in renewable energy systems, such as solar and wind power systems, to recharge the battery when the renewable energy source is not generating power.

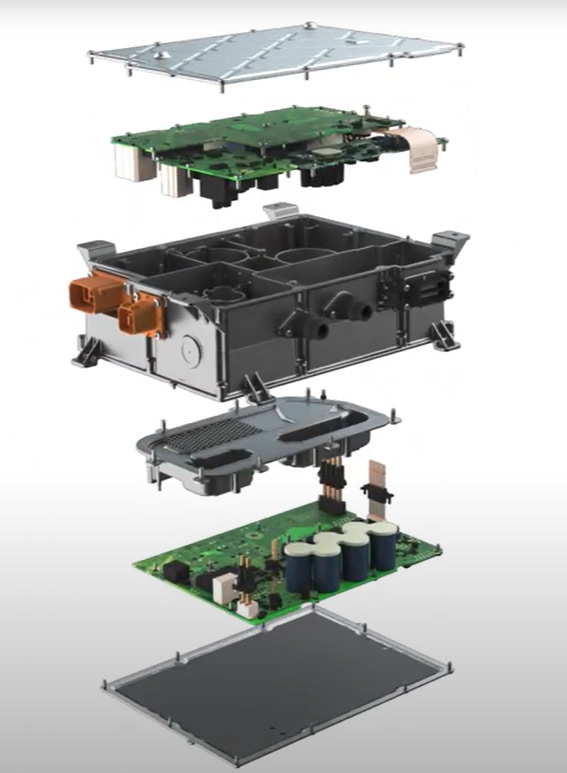

About Elecpeek’s OBC

Features

Supports UDS Diagnosis with CAN Wake-up Function

Equipped with support for the vehicle diagnostic system and features CAN bus wake-up functionality.

Fully Sealed Process, Reliable Operation in Extreme Temperatures

Utilizes a fully sealed process, ensuring reliable operation even in extreme temperature conditions ranging from -40℃ to 60℃.

Built-in Heat Sensor, Automatic Shutdown at 90℃

Integrates a heat sensor that automatically shuts down when the temperature reaches 90℃ to prevent overheating.

Protection Level IP67

Possesses a high protection level, meeting IP67 standards for dust and water resistance.

Advantages

Cost-Effective:

Provides cost-effective solutions.

Customizable:

Offers customizable features in both software and hardware aspects to meet diverse requirements.

Compliance with EMC Legal Requirements:

Meets legal requirements for electromagnetic compatibility (EMC).

Developed Specifically for Automotive OEMs and System Integrators

Tailored for automotive Original Equipment Manufacturers (OEMs) and system integrators, meeting their specific needs.

Prodrive Technology Fully Aligns with Long-Term Partner Requirements:

Prodrive’s technology aligns comprehensively with the stringent conditions of long-term partners, addressing challenges in carbon neutrality and intelligent transportation transformations.

Applications

- Electric vehicles

- Three-wheelers

- Electric motorcycles

- Bicycles

- Construction vehicles

- Energy storage systems

- Electric yachts

- Off-road solutions

Customization

Software Section

Tailored software support to accommodate variations in vehicle models and battery control protocols.

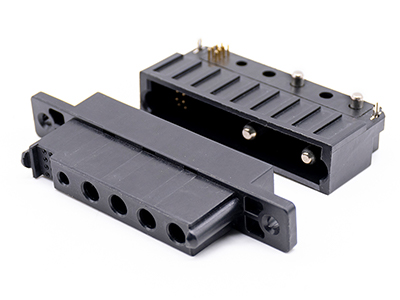

Hardware Section

Interfaces and connectors can be customized as per requirements. The housing is a die-cast component, and the connector base is CNC machined, with external manufacturing handled by outsourcing.

Elecpeek specializes in designing, manufacturing, and marketing innovative products, including NEW Energy Electric Vehicle Connectors, HV Energy Storage Battery Connectors, Power Cable Connectors, Quick Connect Connectors, and HVIL High Voltage Current EV Charger Connectors.

*For detailed information about our products or assistance, feel free to engage with our technical staff in real-time through our website or by sending an email to [email protected]. The entire Elecpeek team is eager to collaborate with you.